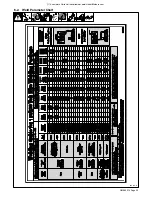

.

A complete Parts List is available at www.HobartWelders.com

OM-260 274 Page 14

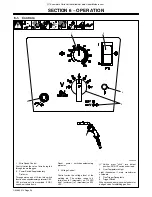

SECTION 5

−

INSTALLATION

!

Special installation may be

required where gasoline or

volatile liquids are present

−

see NEC Article 511 or CEC

Section 20.

!

Do not move or operate unit

where it could tip.

1

Line Disconnect Device

Locate unit near correct input power

supply.

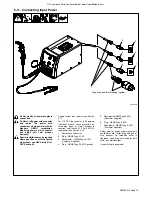

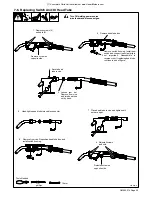

5-1. Selecting A Location

1

18 in

(460 mm)

18 in

(460 mm)

Location And Airflow

250 3322-B / ST-139 445-E

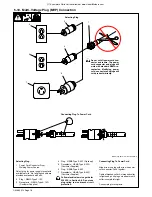

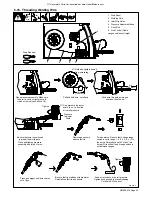

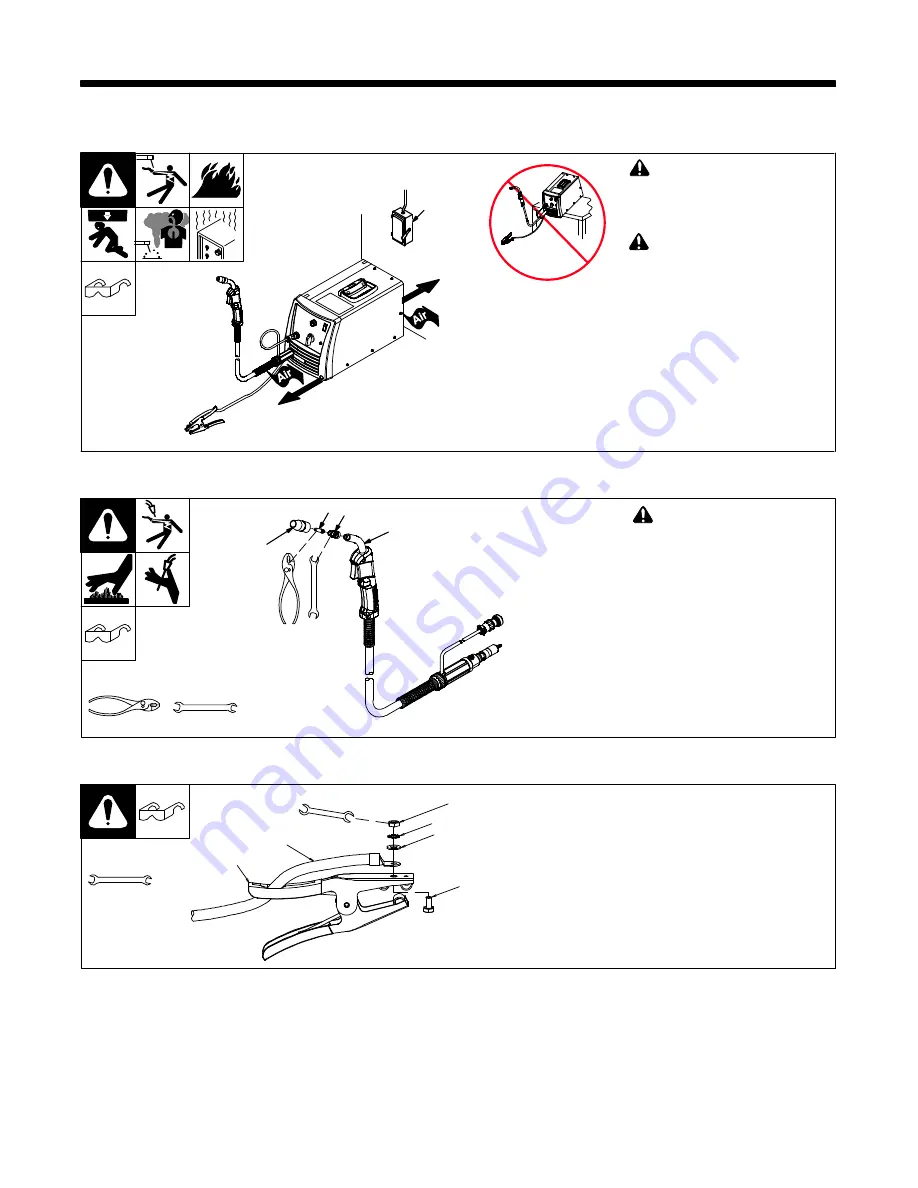

5-2. Installing Nozzle, Contact Tip, And Adapter

Ref. 243 839-A

!

Turn off welding power

source.

1

Nozzle

2

Contact Tip

3

Tip Adapter

.

Wire size stamped on tip

−

check

and match wire size.

Tools Needed:

8 mm

Head

Tube

8 mm

1

3

2

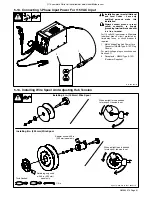

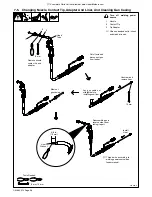

5-3. Installing Work Clamp

258 550-A

1

2

3

4

5

6

1

Work Clamp

2

Work Cable From Unit

3

Screw

4

Flat Washer

5

Lock Washer

6

Nut

Route work cable through

hole in clamp handle. Secure

cable with hardware as

shown.

.

Connection hardware

must be tightened with

proper tools. Do not just

hand tighten hardware.

A loose electrical

connection will cause

poor weld performance

and excessive heating of

the work clamp.

Tools Needed:

10 mm