OM-260 274 Page 33

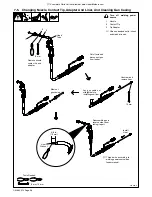

9-3.

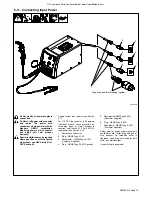

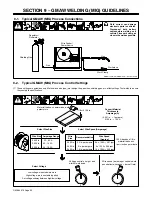

Holding And Positioning Welding Gun

.

Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trigger, be sure wire is no more than 1/2 in. (13 mm)

past end of nozzle, and tip of wire is positioned correctly on seam.

1

Hold Gun and Control Gun

Trigger

2

Workpiece

3

Work Clamp

4

Electrode Extension (Stickout)

Solid Wire

−

3/8 to 1/2 in.

(9 to 13 mm)

5

Cradle Gun and Rest Hand on

Workpiece

2

3

5

4

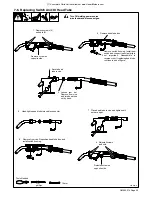

90

90

0

-15

45

45

1

0

-15

S-0421-A

End View of Work Angle

Side View of Gun Angle

GROOVE WELDS

End View of Work Angle

Side View of Gun Angle

FILLET WELDS

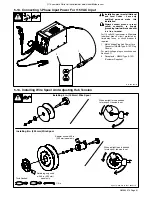

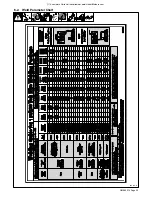

9-4.

Conditions That Affect Weld Bead Shape

.

Weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base metal, wire feed speed

(weld current), and voltage.

Slow

FILLET WELD ELECTODE EXTENSIONS (STICKOUT)

ELECTRODE EXTENSIONS (STICKOUT)

GUN ANGLES AND WELD BEAD PROFILES

10

10

GUN TRAVEL SPEED

S-0634

Push

Perpendicular

Drag

Short

Normal

Long

Short

Normal

Long

Normal

Fast