SUBJECT

CHAPTER/SECTION

PAGE

E. Electric Governor System Adjustment . . . . . . . 2-3 . . . . . . . . . . . . . . . . . 10

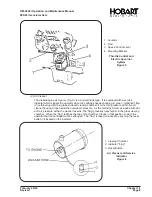

(1) Actuator linkage adjustment

2-3

11

(2) Magnetic pickup adjustment

2-3

11

(3) Governor Control Unit Adjustment

2-3

13

(4) Magnetic pickup signal

2-3

13

4. Generator and Exciter Test

2-3

15

5. Diode Test

2-3

15

6. Test and Adjustment of Transformer-

Rectifiers

2-3

16

7. Additional Tests for Dual Output Units

2-3

16

CHAPTER 3. TROUBLESHOOTING

SECTION 1. TROUBLE SHOOTING

PROCEDURES

3-1

1

1. General

3-1

1

2. Trouble Shooting Chart (Figure 2)

3-1

1

A. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . . . . . . . . . . . . . . 1

B. Use of the Trouble Shooting Chart . . . . . . . . . . 3-1 . . . . . . . . . . . . . . . . . . 1

3. Equipment for Troubleshooting

3-1

2

4. Safety - WARNING:

3-1

2

5. Parts Replacement

3-1

2

6. Test Values

3-1

2

7. Checking Connections and Leads

3-1

3

8. Electric Governor Trouble Shooting

3-1

3

9. Engine Trouble Shooting Procedures

3-1

3

A. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . . . . . . . . . . . . . . 3

B. Locating a Misfiring Cylinder . . . . . . . . . . . . . . . 3-1 . . . . . . . . . . . . . . . . . . 3

C. Checking Compression Pressure . . . . . . . . . . . 3-1 . . . . . . . . . . . . . . . . . . 4

D. Interpretation of Compression

Pressure Records . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . . . . . . . . . . . . . . 4

E. Causes of Low Cylinder Pressure . . . . . . . . . . . 3-1 . . . . . . . . . . . . . . . . . . 5

F. Fuel Flow Test (see Fig. 7) . . . . . . . . . . . . . . . . . 3-1 . . . . . . . . . . . . . . . . . . 4

10.Illustrations

3-1

5

11. Troubleshooting Transformer-

Rectifiers (T-R’s)

3-1

5

OM-2040 / Operation and Maintenance Manual

90D20 / Generator Sets

Table of Contents

February 28/94 Revised

Page 6

Summary of Contents for 6921 Series

Page 2: ...This page intentionally left blank ...

Page 223: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 227: ......

Page 228: ......

Page 229: ......

Page 230: ......

Page 231: ......

Page 232: ......

Page 233: ......

Page 234: ......

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 241: ......

Page 242: ......

Page 243: ......

Page 244: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 249: ......

Page 250: ......

Page 251: ......

Page 252: ......

Page 253: ......

Page 254: ......

Page 255: ......

Page 256: ......

Page 257: ......

Page 258: ......

Page 259: ......

Page 260: ......