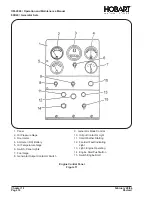

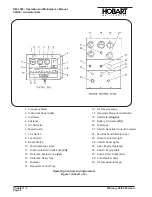

d. Indicating lights

A green indicating light

(13, Fig. 11)

glows to indicate that power is available to the engine

protective system. The light operates only when the engine is running and fuel pressure is

sufficiently high to close a fuel pressure switch

(19, Fig. 4)

. The purpose of the pressure

switch is to deactivate the protective circuit when the engine is stopped and prevent

discharge.

e. Fuel gage and blocking diodes

An electric fuel gage

(7, Fig. 11)

receives a signal from the sending unit mounted on the fuel

tank. Twelve-Volt DC operating power is supplied to the fuel gage system. To check fuel

quantity while engine is stopped, use switch

(6)

to turn ON panel lights.

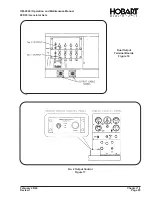

A blocking diode

(10, Fig. 14)

, located on the back of the fuel gage, prevents feedback from

the alternator into the engine circuitry.

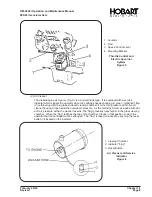

f. Cold weather starting aid control (Optional)

The push-button control

(11, Fig. 11)

operates a cold weather starting aid. The starting aid

consists of a group of items designed to inject a highly volatile fluid into the engine air intake

system. This assists ignition of fuel when air temperature is too low for the heat of

compression to ignite a normal fuel mixture. The starting aid consists of a cylindrical fluid

container and a valve

(see 6, Fig. 3)

which are mounted on the panel separating the

generator from the engine. The valve is operated by the control

(11, Fig. 11)

allowing fluid to

flow into the valve. Pushing the button IN forces fluid through a small tube and an atomizing

nozzle into the inlet manifold. The addition of atomized, highly volatile fuel into the inlet air

assists in igniting the diesel fuel mixture.

g. Engine stop control

The engine is normally stopped by use of the 3 position switch. Top position is START,

middle is RUN and bottom position is STOP.

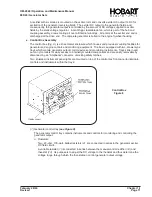

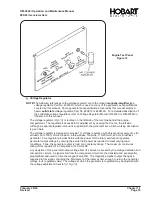

h. Air cleaner indicator

The air cleaner indicator

(See 1, Fig. 12)

is mounted on the engine test panel. Its function

was explained in Para. 5, (3), See Fig. 5.

i.

Test receptacle connector

This amphenol connector (

1, Fig. 12)

provides an attaching point for leads which are

connected to selected test points throughout the engine and generator electrical systems.

Connections and schematic diagrams indicate points at which the leads are connected. The

receptacle connector is designed to mate with a test box plug connector

(See Fig. 15)

.

OM-2040 / Operation and Maintenance Manual

90D20 / Generator Sets

February 28/94

Chapter 1-1

Revised

Page 17

Summary of Contents for 6921 Series

Page 2: ...This page intentionally left blank ...

Page 223: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 227: ......

Page 228: ......

Page 229: ......

Page 230: ......

Page 231: ......

Page 232: ......

Page 233: ......

Page 234: ......

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 241: ......

Page 242: ......

Page 243: ......

Page 244: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 249: ......

Page 250: ......

Page 251: ......

Page 252: ......

Page 253: ......

Page 254: ......

Page 255: ......

Page 256: ......

Page 257: ......

Page 258: ......

Page 259: ......

Page 260: ......