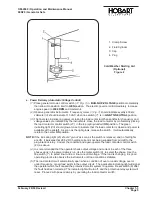

b. Cartridge Installation

(See Fig. 4)

(1)

Carefully install the new cartridge into the housing. Avoid bumping the cartridge tubes against

the housing sealing flange. Seat the cartridge properly within the housing. Press all edges and

corners of the cartridge firmly with fingers to effect a positive air seal against the sealing flange of

the housing.

Under no circumstances should the cartridge be pounded or struck in the center

to effect a seal.

(2)

Lock the cartridge in place by installing the baffle assembly

(3)

and clamp assembly

(2)

with cup

assembly

(1)

in place. Tighten clamp

(2)

down in place.

5. Engine Fuel

a. Quality

The quality of fuel oil used in the diesel engine is a major factor in long engine life and performance.

Fuel oil must be clean, completely distilled, stable, and non-corrosive. Only distillate fuel No. 1d is

recommended for use both summer and winter.

Consult the “fuel oil selecting chart” in the engine operator’s manual before

substituting another grade of fuel.

6. Generator Maintenance

The 400-Hz generator requires no maintenance or service other than periodic cleaning. The unit is

brushless, and bearings are permanently lubricated and sealed.

a. Cleaning

The generator may be cleaned by careful use of compressed air and/or a good, SAFE commercial

cleaner. Steam cleaning of the generator is not recommended because steam and harsh chemical

compounds may damage insulation and other generator components.

Electric shock and fire can kill or injure! Be sure the unit is completely dry

before operating. Do not use a flammable solvent.

b. Adjustment

The generator itself requires no adjustment. Adjustment procedures for generator controls are

covered in Section 2-3.

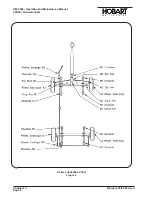

7. Drive Belts

To check V-belts, it is necessary to remove rear access panel cover on left side of canopy. The engine

cooling fan is driven by a matched set of V-belts. The 12 V-DC alternator is driven by a single V-belt.

a. Fan Belts

No adjustment is necessary for fan belts. Proper tension is maintained on these belts by the idler

pulley

(Section 1-1, Item 10, Fig. 4).

b. Check Belt Tension

Check tension by pressing the thumb

(Fig. 6)

midway between the pulleys. Maximum allowable

inward deflection of this belt is 15mm

(0.6 in.)

CAUTION

CAUTION

WARNING

OM-2040 / Operation and Maintenance Manual

90D20 / Generator Sets

February 28/94 Revised

Chapter 2-1

Page 9

Summary of Contents for 6921 Series

Page 2: ...This page intentionally left blank ...

Page 223: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 227: ......

Page 228: ......

Page 229: ......

Page 230: ......

Page 231: ......

Page 232: ......

Page 233: ......

Page 234: ......

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 241: ......

Page 242: ......

Page 243: ......

Page 244: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 249: ......

Page 250: ......

Page 251: ......

Page 252: ......

Page 253: ......

Page 254: ......

Page 255: ......

Page 256: ......

Page 257: ......

Page 258: ......

Page 259: ......

Page 260: ......