.

A complete Parts List is available at www.MillerWelds.com

OM-244 013 Page 27

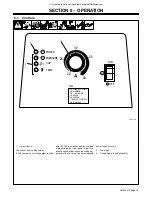

6-3.

Status/Trouble Lights

.

Difficulty establishing a pilot arc may indicate consumables need to be cleaned or replaced.

V

R

E

W

O

P

E

R

U

S

S

E

R

P

P

U

C

P

M

E

T

Light

Condition

Status/Possible Cause

Power

On

Input power is okay.

Pressure/Cup/Temp

Off

When Power light is on, system is normal if these lights

are off.

Power

Flashing rate is steady for 15 seconds or until torch trigger

is pressed again, whichever comes first.

Input power below 156 volts AC, but has returned to

normal.

Power

Repetitive flashing rate of two quick cycles, then a one

second pause.

Input power is below 156 volts AC.

Pressure

On

No or low [below 40 psi (276 kPa)] input pressure.

Pressure

Flashing rate is steady for 15 seconds or until torch trigger

is pressed again, whichever comes first.

Regulated pressure in the unit is low. Check torch for

leaks. Check input pressure to unit is between 90 to 120

psi (621 to 827 kPa).

Pressure

Repetitive flashing rate of two quick cycles, then a one

second pause for a 15 second period.

Regulated pressure in the unit is high. Check input pressure

to unit is between 90 to 120 psi (621 to 827 kPa).

Cup

On

Torch cup is loose or off. Once cup is tightened, unit

power must be cycled off and back on again.

Cup

Flashing rate is steady for 15 seconds or until torch trigger

is pressed again, whichever comes first.

No arc was established. Check consumables or torch.

Cup

Repetitive flashing rate of two quick cycles, then a one

second pause for a 15 second period or until torch trigger

is pressed again, whichever comes first.

No pilot arc established possibly due to a loss of current.

Check consumables.

Cup

Repetitive flashing rate of three quick cycles, then a one

second pause for a 15 second period or until torch trigger

is pressed again, whichever comes first.

Consumables in torch failed to separate during pilot arc

possibly due to being stuck. Check consumables.

Temperature

On

Power source overheated (see Section 4-2). Stop cutting

and allow unit to cool down.

Temperature

On (indefinitely)

Power source temperature sensors may have failed or

ambient temperature is below -22

°

F (-30

°

C).

Temperature

Flashing rate is steady (indefinitely).

Power source temperature sensor provided inaccurate

readings, but returned to normal. Unit power must be

cycled off and back on again.

For system troubleshooting see Section 6-7 and Section 6-8.

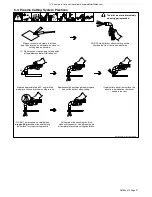

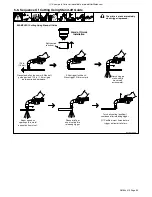

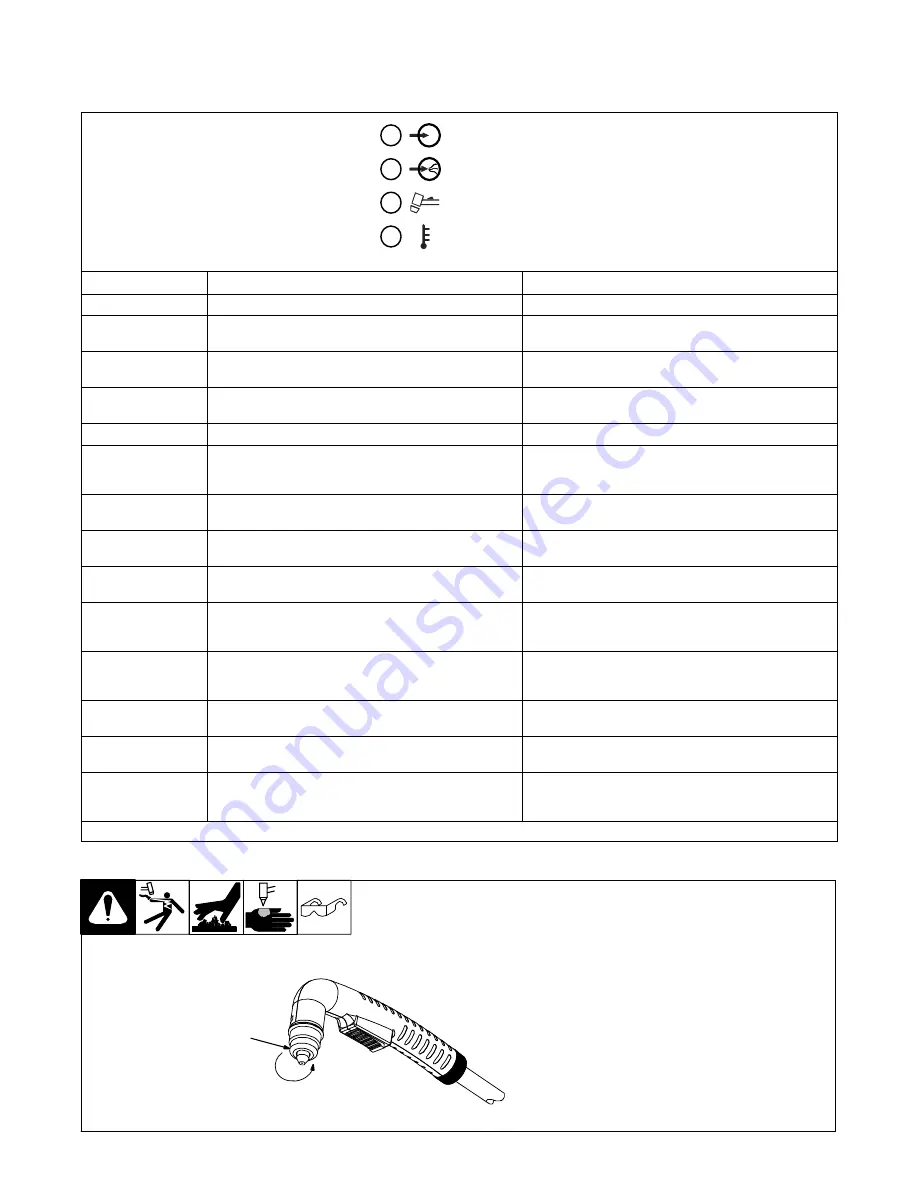

6-4.

Checking Shield Cup Shutdown System

1

Torch Shield Cup

Turn Power On and loosen shield

cup. If shutdown system works

properly, Cup light comes on. If not,

immediately turn Off power and

have Factory Authorized Service

Agent check unit.

If system works properly, retighten

cup and reset power.

Ref. 801 300-A

1

.

Power must be reset whenever the cup

shutdown system is activated.

Always

turn Off power when changing or

checking consumables. Do NOT

overtighten torch shield cup. Gently

finger tighten cup onto torch.