OM-923 Page 11

SECTION 4

−

INSTALLATION

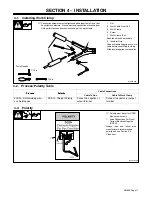

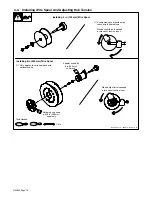

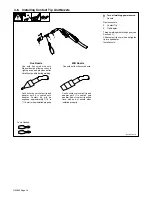

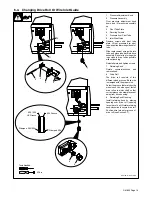

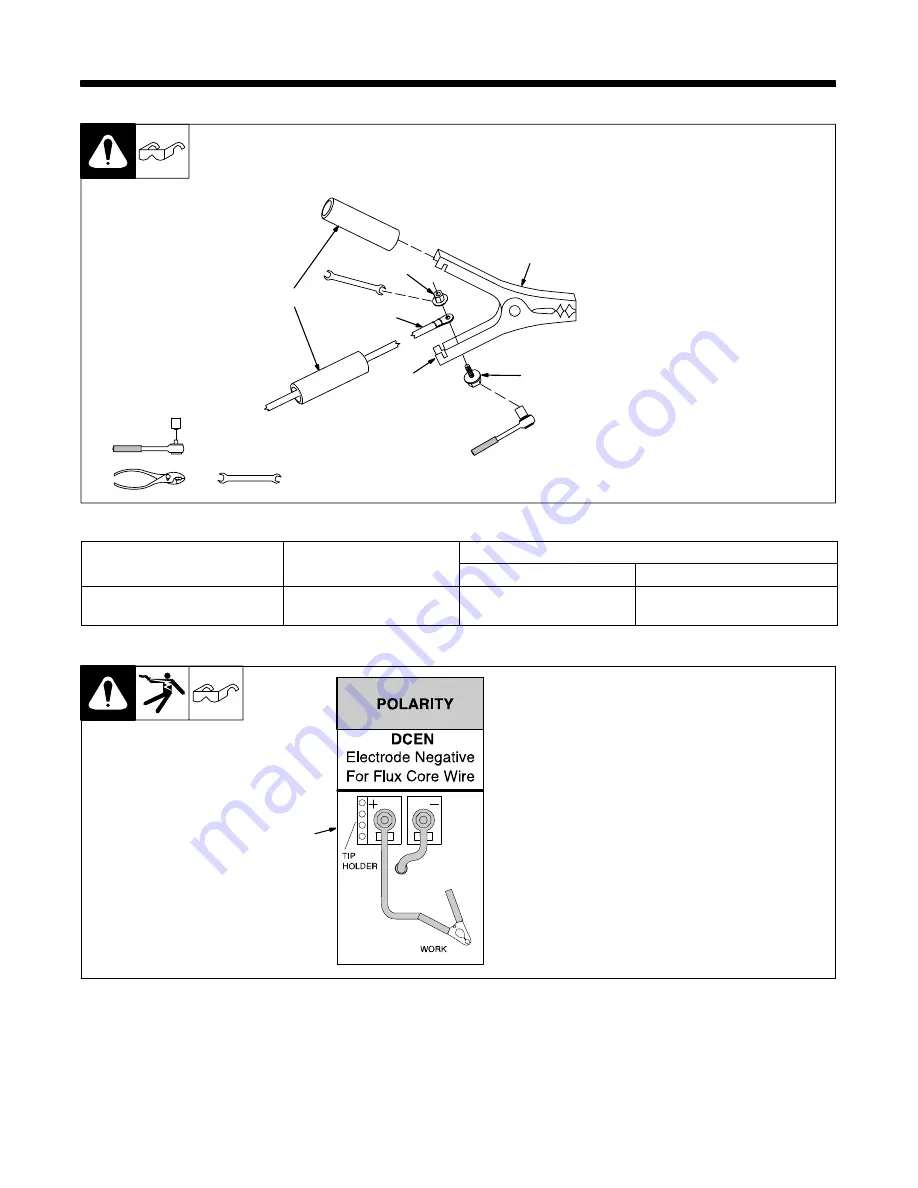

4-1. Installing Work Clamp

1

Nut

2

Work Cable From Unit

3

Work Clamp

4

Screw

5

Work Clamp Tabs

Bend tabs around work cable.

6

Insulator Grip

Slide one insulating grip over work

cable before connecting to clamp.

Slide insulating grips over handles.

Ref. 802 456

1

2

3

4

5

Tools Needed:

7/16 in

6

.

Connection hardware must be tightened with proper tools. Do not just

hand tighten hardware. A loose electrical connection will cause poor

weld performance and excessive heating of the work clamp.

7/16 in

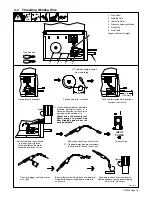

4-2. Process/Polarity Table

Process

Polarity

Cable Connections

Process

Polarity

Cable To Gun

Cable To Work Clamp

FCAW

−

Self-shielding wire

−

no shielding gas

DCEN

−

Straight Polarity

Connect to negative (

−

)

output terminal

Connect to positive (+) output

terminal

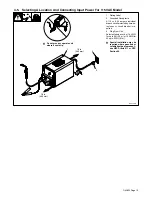

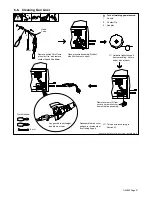

4-3. Polarity

.

Polarity must be set for DCEN

(flux core wire) only.

1

Lead Connections For Direct

Current Electrode Negative

(DCEN)

Always read and follow wire

manufacturer’s recommended

polarity, and see Section 4-2.

Close door.

Ref. 210 428

1