OM-923 Page 21

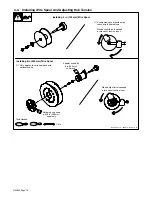

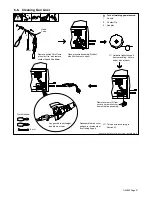

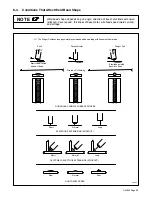

6-6. Cleaning Gun Liner

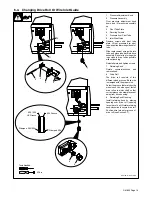

804 241-A / Ref. 804 123-A / 804 128-A / Ref. 803 837-A

Y

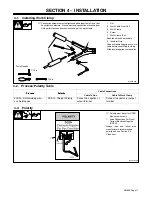

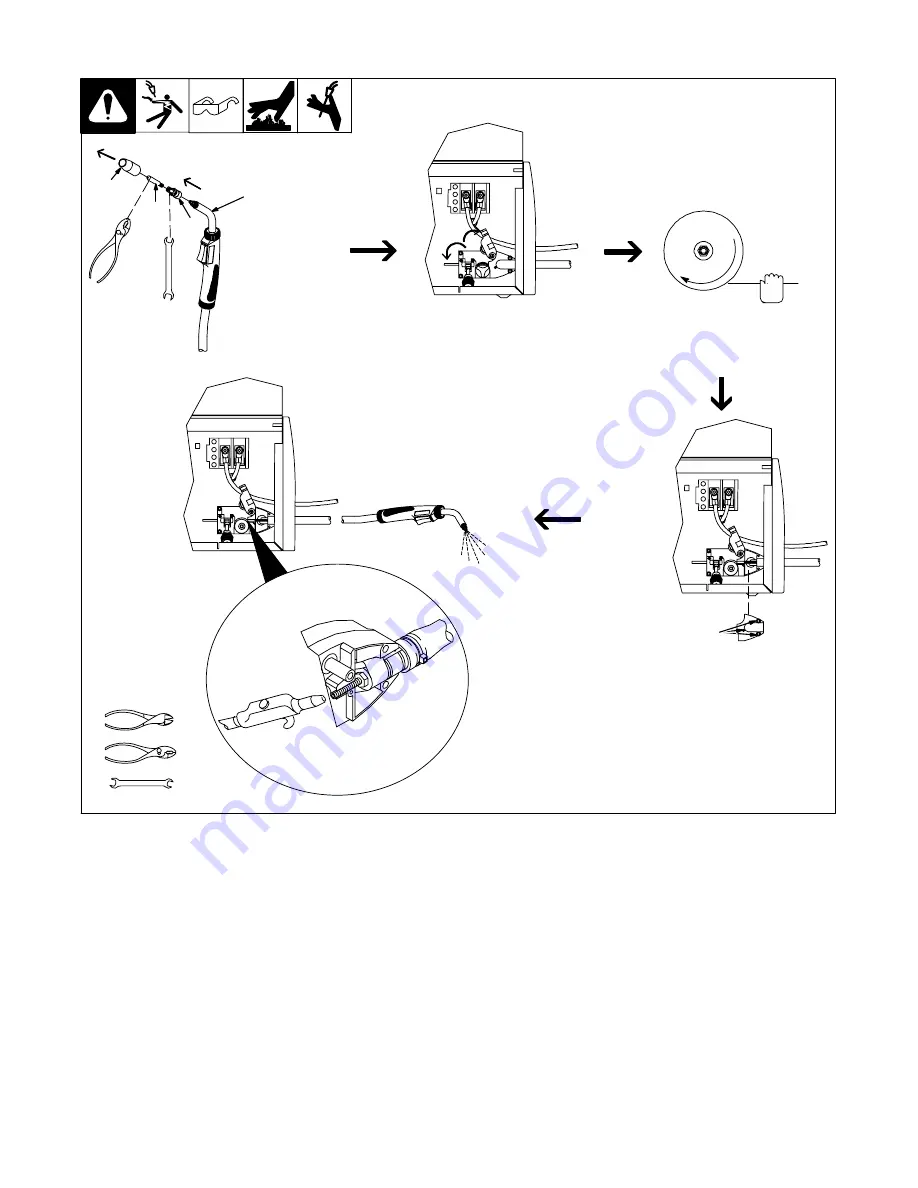

Turn off welding power source.

1

Nozzle

2

Contact Tip

3

Adapter

Head

Tube

Tools Needed:

8 mm

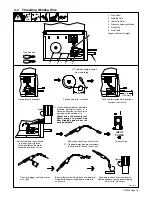

Lay gun cable out straight,

and blow out liner.

Remove nozzle. Cut off wire

at contact tip, and remove

contact tip and tip adapter.

.

Thread wire according to

Section 4-7.

Reassemble drive cover

and gun in reverse order

from taking it apart.

Open pressure assembly. Retract

wire from liner onto spool.

.

Hold wire tightly to keep it

from unraveling. Secure

end of wire at spool.

Remove screws (3) from

cover, and remove cover

from wire drive assembly.

8 mm

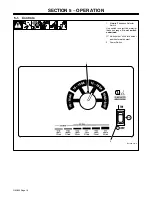

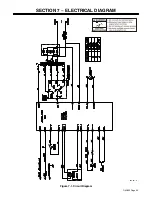

1

2

3

+

−

+

−

+

−