2

Flux Cored

E71T-11

(DCEN)

Solid Wire

ER70S-6

(DCEP)

Solid Wire

ER70S-6

(DCEP)

Stainless

Steel

(DCEP)

Aluminum**

(DCEP)

Good for windy or

outdoor applications

Produces less spatter.

Better bead appearance.

—

—

—

—

—

1 / 30

2 / 30

2 / 20

3 / 50

3 / 35

3 / 30

3 / 40

4 / 30

3 / 40

3 / 20

4 / 70

4 / 40

4 / 40

4 / 40

4 / 35

4 / 45

4 / 35

—

—

—

—

—

—

4 / 50*

—

—

—

—

4 / 30

—

—

—

—

—

2 / 30

2 / 20

—

—

1 / 25

—

3 / 40

2 / 30

3 / 25

3 / 30

3 / 20

4 / 25

—

4 / 50

3 / 40

2 / 30

—

—

4 / 30

3 / 10

2 / 15

—

4 / 90**

3 / 90**

—

2 / 30

—

—

—

—

—

—

—

—

—

—

—

—

CFH

Settings are approximate. Adjust as required. Thicker materials can be

welded using proper technique, joint preperation and multiple passes.

Recommended Voltage and Wire Speed Settings for thickness of metal being welded.

Number on left of slash is Voltage Setting/Number on right of slash is Wire Feed Setting.

*Multiple passes required. **Aluminum wire is soft so feedability is not as good. Make sure that hub tension is not too tight and keep the torch as straight as possible. A “push angle” for the torch is recommended.

Match feed roll groove to diameter of wire being used.

Set tension knob setting to 3 at start.

Adjust tension per instructions in the manual.

CAUTION!

Do not change voltage switch

position while welding. See owners manual

for more information.

Wire speed listed is a starting value only.

Wire speed setting can be

fine-tuned while welding. Wire speed also depends on other variables

such as stick out, travel speed, weld angle, cleanliness of metal, etc.

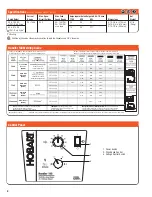

Handler 140 Welding Guide

Control Panel

1. Power Switch

2. Wire Speed Control

3. Voltage Control Switch

1

2

3

Certified by Canadian Standards Association to both the Canadian and U.S. Standards.

*

CSA rating.

Specifications

(SUBJECT TO CHANGE WITHOUT NOTICE.)

Rated Output

90 A, 19 VDC,

at 20% Duty Cycle

63 A, 21 VDC

at 20% Duty Cycle*

Max. Open-

Circuit Voltage

28 V

Wire Feed

Speed Range

40 – 700 IPM

50 – 740 IPM

at no load

Current

Range

25 – 140 A

Amps Input at Rated Output, 60 Hz, 1-Phase

115 V

KVA

KW

20

2.9

2.5

15*

2.2*

1.77*

Dimensions

H: 12-3/8 in. (315 mm)

W: 10-5/8 in. (270 mm)

D: 19-1/2 in. (495 mm)

Net

Weight

57 lb.

(26 kg)