OM-240 362 Page 11

SECTION 7

−

INSTALLING OPTIONAL MAGNIFYING LENS

1

Optional Magnifying Lens

Starting at the bottom, slide magni-

fying lens into the helmet retaining

brackets. Align the magnifying lens

with the auto-darkening lens as-

sembly.

D

Remove lens holding frame

(with auto-darkening lens)

from helmet shell.

D

Remove auto-darkening

lens from lens holder.

D

Position lens holder with

magnifying lens holding

tabs facing toward you.

From the bottom up, slide

magnifying lens into posi-

tion. (Slide magnifying lens

up or down slightly as de-

sired.)

D

Reinstall the auto-darkening

lens in the lens holder.

D

Reverse procedure to re-

move magnifying lens.

.

To prevent lens fogging, install

flat side of magnifying lens to-

ward auto-darkening lens.

804 818

1

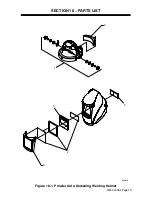

SECTION 8

−

MAINTENANCE

NOTICE

−

Never use solvents or abrasive cleaning detergents.

NOTICE

−

Do not immerse the lens assembly in water.

The helmet requires little maintenance. However, for best performance clean

after each use. Using a soft cloth dampened with a mild soap and water solution,

wipe the cover lenses clean. Allow to air dry. Occasionally, the filter lens and

sensors should be cleaned by gently wiping with a soft, dry cloth.