CONTROL ROD ADJUSTMENT RADIO INSTALLATION

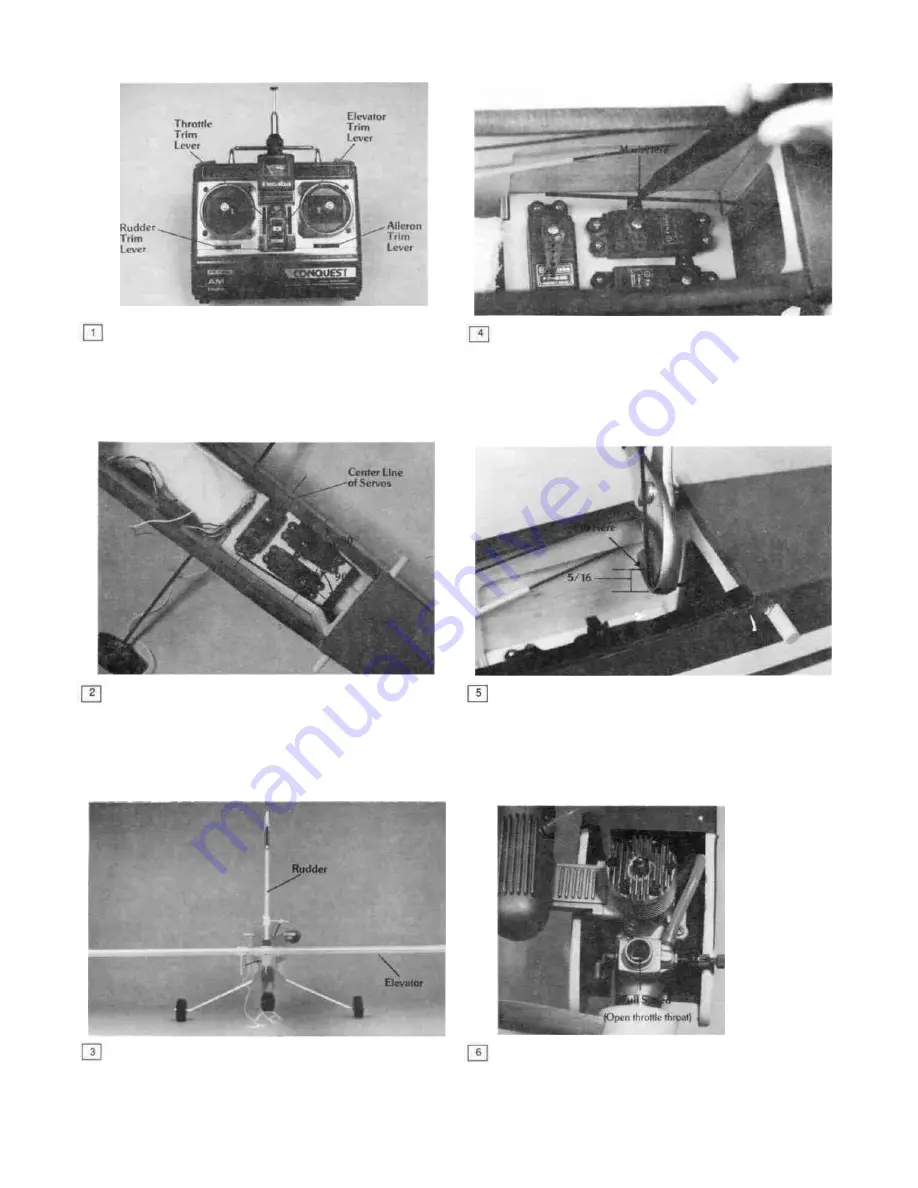

Be sure that your radio system is fully charged and the servos are plugged into

the receiver Turn on the transmitter then receiver Set the trim levers to the

neutral position Turn the receiver then the transmitter back off

If using the Snap R' Keeper mark on the push rod where the hole in the servo

arm is

Adjust the servo arms so that they are positioned as shown above The screw

holding the arm on may need to be removed so that the arm can be removed and

adjusted

Make a 90° bend at the mark on the push rods Cut the excess wire as shown,

and install the Snap R Keepers to the rod and servo arms following the

manufacturers instructions If using E Z connectors install them on the servo

arms and attach the rods following the manufacturer's instructions

Set the rudder and elevator so that they are in the neutral position as shown

With the transmitter and receiver on set the throttle to full speed on the

transmitter Set the throttle arm on the carburator to full power Install the push

rod as instructed in previous step.

15

Summary of Contents for avistar 40

Page 20: ......