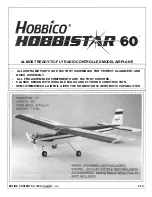

4. Using the same scrap of plywood, apply an even coat of epoxy to the

top and bottom of the horizontal stabilizer in the area where you

removed the covering.

INSTALLATION OF VERTICAL STABILIZER

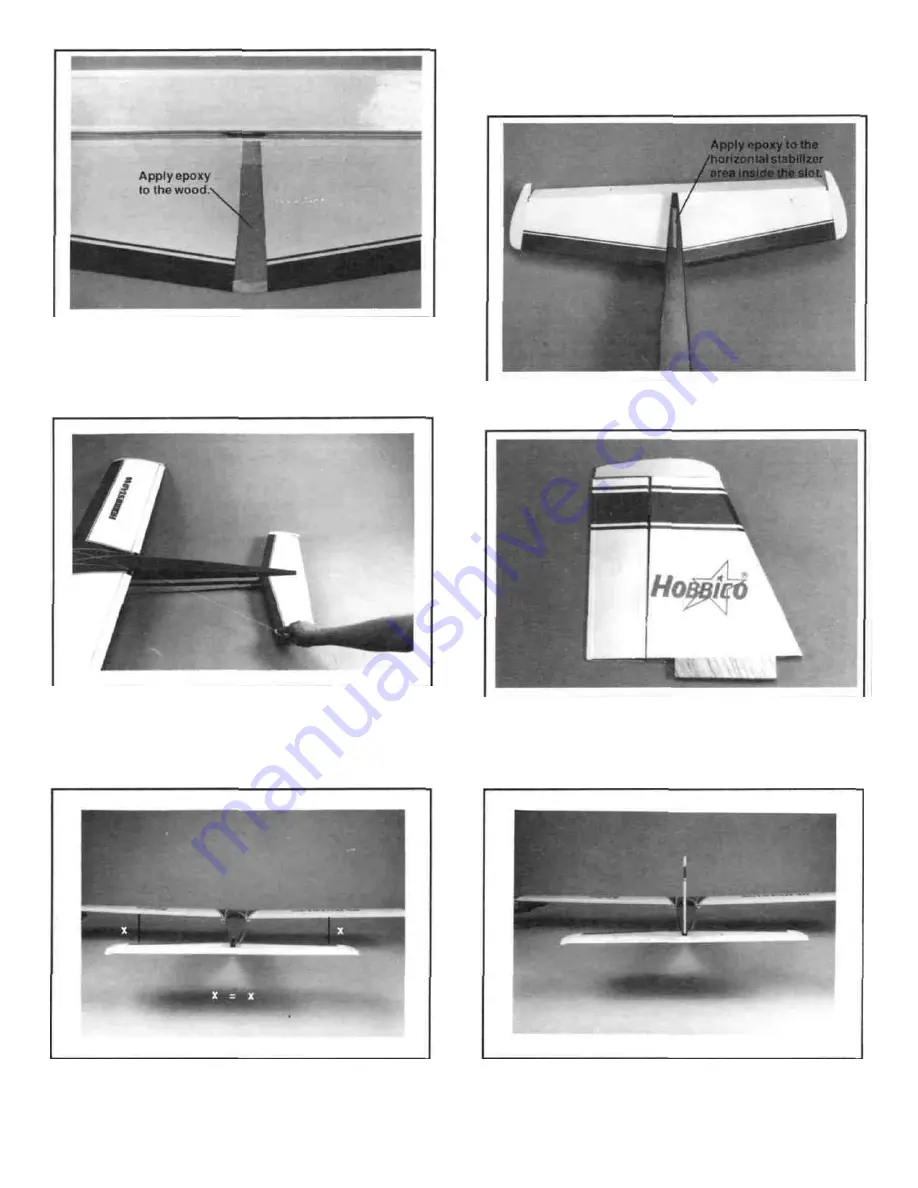

Now if we have done a good job with the wing-stabilizer relationship, the

installation of the rudder should be easy. The vertical stablilizer is 90' to

the wing. A drafting triangle would be helpful here.

5. Slide the stabilizer into the slot from the rear. This fit should be close

but not tight. Using a ruler (12") check to see if you have equal

distance from the center of the tail to the outside edge of the stab.

Now using the string explained in the stabilizer preparation section,

adjust the stabilizer so it is 90' to the center line of the fuselage.

1. Looking into the fuselage vertical stabilizer slot, apply some epoxy

to the top surface of the horizontal stabilizer that is visible inside the

fuselage.

2. Mix a small batch of epoxy and apply it to the area inside of the

fuselage on the surface of the exposed wood. Apply an even coat

to the vertical stabilizer base where you removed the covering. Inset

the vertical stabilizer into the slot and push down until the stabilizer

stops.

6. Now view the stabilizer-wing relationship from behind with the plane

resting on a level surface (see photo above). Distance "x" should be

the same. If not, shim the stabilizer using a small sliver of wood to

get the proper relationship. Let the epoxy cure thoroughly.

3. Using the triangle, check to see if the rudder is 90* to the horizontal

stabilizer. If so, a couple of straight pins will hold the rudder in

position until the epoxy cures.

-10-