12

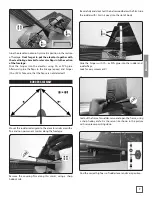

BALANCE THE MODEL (C.G.)

More than any other factor, the C.G. (balance point) can

have the greatest effect on how a model flies and may

determine whether or not your first flight will be successful.

If you value this model and wish to enjoy it for many flights,

DO NOT OVERLOOK THIS IMPORTANT PROCEDURE. A

model that is not properly balanced will be unstable and

possibly unflyable.

At this stage the model should be in ready-to-fly condition

with all of the systems in place including the engine, landing

gear, covering and the radio system.

❍

1. Use a felt-tip pen or 1/8"-wide tape to accurately mark

the C.G. on the top of the wing. The C.G. is located 65 mm

back from the leading edge of the wing.

❍

2. With the wing attached to the fuselage, all parts of

the model installed (ready to fly) and with batteries in

position, place the model upside-down on a Great Planes

CG Machine, or lift it upside-down at the balance point

you marked.

❍

3. If the tail drops, the model is “tail heavy” and the battery

pack and/or receiver must be shifted forward or weight

must be added to the nose to balance. If the nose drops,

the model is “nose heavy” and the battery pack and/or

receiver must be shifted aft or weight must be added to

the tail to balance. If possible, relocate the battery pack

and receiver to minimize or eliminate any additional

ballast required. If additional weight is required, nose

weight may be easily added by using a “spinner weight”

(GPMQ4645 for the 1 oz. weight, or GPMQ4646 for the

2 oz. weight). If spinner weight is not practical or is not

enough, use Great Planes (GPMQ4485) “stick-on” lead. A

good place to add stick-on nose weight is to the firewall

(don't attach weight to the cowl–it is not intended

to support weight). Begin by placing incrementally

increasing amounts of weight on the bottom of the fuse

over the firewall until the model balances. Once you

have determined the amount of weight required, it can

be permanently attached. If required, tail weight may be

added by cutting open the bottom of the fuse and gluing

it permanently inside.

Note: Do not rely upon the adhesive on the back of the

lead weight to permanently hold it in place. Over time, the

adhesive may softern and cause the weight to fall off. Use

#2 sheet metal screws, RTV silicone or epoxy to permanently

hold the weight in place.

❍

4. IMPORTANT: If you found it necessary to add any

weight, recheck the C.G. after the weight has been

installed.

BALANCE THE MODEL LATERALLY

❏

❏ ❏

1. With the wing level, have an assistant help you lift

the model by the engine propeller shaft and the bottom of the

fuse under the TE of the fin. Do this several times.

❏

❏ ❏

2. If one wing always drops when you lift the model,

it means that side is heavy. Balance the airplane by adding

weight to the other wing tip. An airplane that has been laterally

balanced will track better in loops and other maneuvers.

SET THE CONTROL THROWS

Use a ruler to accurately measure and set the control throw

of each control surface as indicated in the chart that follows.

If your radio does not have dual rates, we recommend setting

the throws at the low rate settings.NOTE: The throws are

measured at the widest part of the elevators, rudder and

ailerons.

ENGLISH

Summary of Contents for Midi EDGE 540 FLWA4001

Page 15: ...15 PERSONAL NOTES ENGLISH...

Page 16: ...Distributed by www hobbico de...