5

WINGS ASSEMBLY

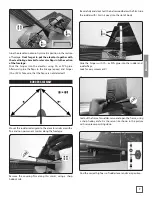

Glue the hinges into the slots in wing and aileron, using CA

or PVA glue. The glue should be very liquid for better glueing

results.

Mount the aileron servo as shown in the picture with 2 screws.

Search the center position with servo tester or RC and attach

the servo lever parallel to the aileron.

During assembly, look for correct angles and position of the

aileron. If the aileron is in neutral position, the servo lever and

the linkage should include an angel of 90 degrees.

CHOOSING THE MOTOR SET

If you choose a motor for back mount like the motor from

speed motorset, you have to use the shorter motordome

which is attached as milling parts in the box of accessories.

The longer, just assembled motor dome is only for front

mounting of brushless motors with 28mm diameter.

ENGLISH

Summary of Contents for Midi EDGE 540 FLWA4001

Page 15: ...15 PERSONAL NOTES ENGLISH...

Page 16: ...Distributed by www hobbico de...