The Hobbico NexSTAR Select can also be equipped with

dual aileron servos and flaps. To set up the airplane this

way, you need to follow the above instructions for the dual

servo installation and then install the flaps as indicated

below. The necessary hinges on the wing were located

where needed when the wing was built.

For this section you will need :

❏

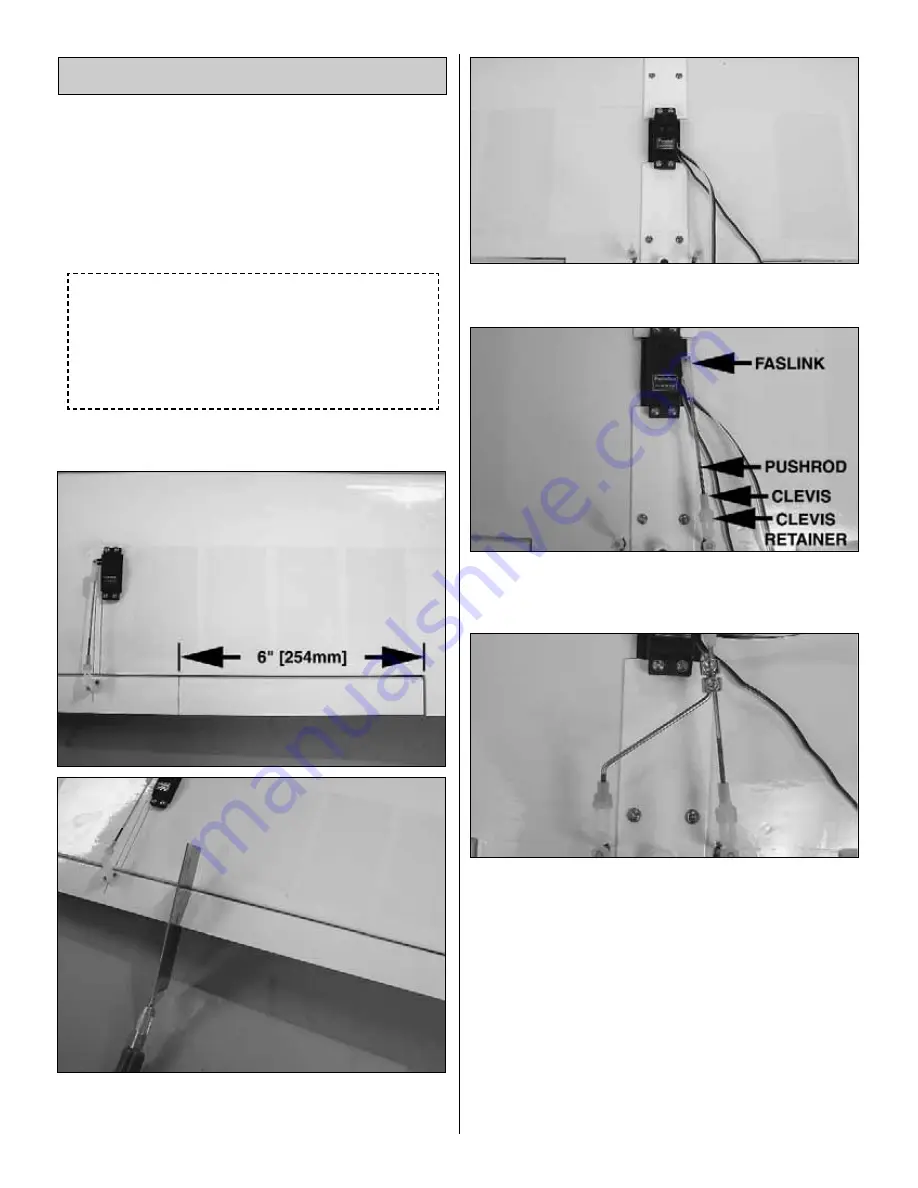

1. Draw a line on the aileron 10" [254mm] away from the

aileron end at the root and use a hobby saw to cut the

aileron at that line.

❏

2. Install the flap servo in the center of the wing, where

the original aileron servo was.

❏

3. Using one of the 6" [152mm] pushrods, a nylon clevis,

clevis retainer and a Faslink make a pushrod and connect it

to the flap servo and flap horn as shown above.

❏

4. Bend the second pushrod as shown above and

connect it to the first with two 5/32"[4mm] wheel collars.

Tighten the two 6-32x1/4" [6.4mm] socket head cap screws

to secure the two flap pushrods together as shown above.

❏

5. The flaps should only be able to move down 1/2" [13mm].

There is no up movement for the flaps.

Flap installation is finished.

Note: To install dual servo and flaps, you will need to

upgrade to a 6 Channel radio. In this case, the two aileron

servo leads will connect to two different channels in your

receiver and then the flap servo to another channel. Follow

your radio manufacturer's instructions to set up the aileron

mixing and flaps in your Hobbico NexSTAR Select.

1 Additional servo to be

used for flaps.

1 6"[152mm] Servo

Extension

2 6"[152mm] Pushrods

2 Nylon Clevises

1 Faslink

2 5/32"[4mm] Wheel

Collars

2 6-32x1/4" [6.4mm]

Socket Head Cap

Screws.

1 Screwdriver

Dual Aileron Servos & Flaps

26

Summary of Contents for Nexstar select

Page 28: ...28 Correct Angle Rods Fin ...