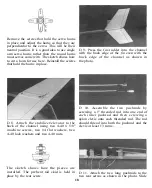

D 4. Epoxy the two 11/32" x 2" x 1-5/8"

Tapered TE Supports to the inboard bottom of

each center trailing edge as shown in the photo.

D 6. Hold the 3/8" x 1-1/4" x 22-1/4" Ailerons

in place against the sub trailing edge and under

the torque rods. Mark the location where the

torque rods will enter the ailerons. Drill a 3/32"

hole in each aileron to accept the torque rods.

D 5. Use a sanding block with 150-grit

sandpaper to sand the inner ends of the sub

trailing edge. center trailing edge and the

tapered trailing edge to match the angle of

the foam wing end. Be careful not to change

the angle of the foam wing.

AILERON

22-1/2" Long

ARF2W04

D 7. Cut a groove in the leading edge of the

aileron to allow clearance for the torque rods.

Trial fit the ailerons in place and cut as

necessary until they fit.

D 8. Draw an accurate centerline along the

leading edge of the aileron and cut three

hinge slots in each aileron. The hinge slots

should be approximately 1-1/2", 10" and 18"

from the wing tip. Place the ailerons against

the sub trailing edge and mark the hinge

locations on the wing. Draw a center line

down the sub trailing edge and cut the hinge

slots to match the ailerons.

D 9. Using a sanding block, sand the leading

edge of each aileron to a "V" shape.

11