proper reinforcement. Make sure the tape is

applied with no wrinkles and that the strips

are straight and parallel from wingtip to

wingtip. If this tape is not applied, if it is

applied incorrectly or if a different type of

tape is applied, we cannot be responsible

for any wing failure that may occur.

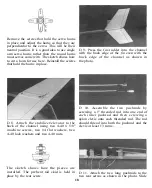

D 5. Place the wing upside down on the edge

of a table so that only 1/2 of the wing (from

one wing tip to the center joint) is resting on

the table. Starting at the wing tip that is

resting on the table, lay a strip of nylon-

reinforced strapping tape down so that it

crosses over the center joint directly over the

wing joiner.

Press the tape firmly onto the wing and down

into the fillet (where the bottom of the wing

meets the mounting platform) and then flip

the wing around and continue the strip of

tape out to the other wing tip. Apply two

more strips of tape between this strip and the

trailing edge of the wing. The fourth strip

should be added between the first strip and

the leading edge of the wing. The previous

photo shows where the strips should be

located. Try to get this tape stuck down

as tightly as possible because it adds a

tremendous amount of strength to the wing

when properly applied. Make sure you do not

change the washout (twist) or dihedral

(V-shape) of the wing when applying the tape

strips. If you are planning on doing some

aerobatics or combat with your STURDY

BIRDY II, you should also put three strips of

tape on the top surface of the wing.

INSTALL THE WING PROTECTOR

D 1. Use a sharp hobby knife or a Dremel®

Tool with a tapered cutting bit to trim out the

servo and torque rod cut-outs in the Plastic

Wing Protector. There are scribe lines on the

bottom surface of the protector to help guide

you. Trial fit the aileron servo in place and

trim as necessary to make it fit properly. Use

scissors or your hobby knife to trim the

outside edges of the wing protector along the

remaining scribe lines.

D 2. Place the wing protector on the center of

the wing so the torque rods fit through their

holes. Draw a line on the wing around the

servo cutout. Remove the protector and carve

out a hole in the foam wing to fit your servo.

Carve out an extra 1/4" square groove in front

and behind the servo cut-out for the servo

rails. Drill a 1/2" diameter hole for the servo

wires down through the front edge of the servo

cutout. Be careful not to cut the plywood wing

joiner when performing these operations.

D 3. Glue the 3/16"x l/4"x 1-1/4" Basswood

Servo Rails in place along the front and back

edges of the servo cut-out. Put the aileron

servo in place and mark on the plastic

protector where the servo mounting screws

should be. Drill 1/1 6" diameter holes on the

marks you just made and mount the servo

using the screws provided with your radio.

D 4. Trial fit the wing protector assembly on

the wing and enlarge the cutouts in the foam

13