the outer pushrod tubes over the inner

pushrod until they are about 1/2" from the

servo end of the inner pushrod.

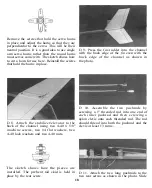

D 12. Press the balsa pushrod holder into

the channel about 6" in front of the fin and

secure the pushrods to it with the nylon tie

wrap. It is a good idea to seal the balsa

pushrod holder with a light coat of epoxy that

will also help hold it in place.

Note: The rudder pushrod goes to the left side

of the fin. The elevator pushrod goes to the

right side (as viewed from the back).

D D 13. Cut 2" off the threaded end of two of

the 12" long link rods. Use a pair of long nose

pliers to bend the "Z" in the unthreaded end

of the 2" pieces.

D 14. Install the link rods in the 2nd hole

from the outer end of each control horn. With

the control surfaces and the servo horns in

their neutral positions, cut the inner pushrod

so the link rod will thread into the inner

pushrod approximately 2/3 of the way.

Install the link rods into the inner pushrods

and adjust so that the control surfaces are at

neutral positions.

D 15. Wrap the receiver in at least 1/4" thick

foam rubber to protect it from vibration, hard

landings, etc. and use two rubber bands to

hold the foam rubber in place. Disconnect

the rudder and elevator pushrods from the

servos and slide the pushrods under the

rubber bands on the top of the receiver.

Position the receiver behind the servos and

reattach the clevises to the servo horns. The

switch can be servo taped to the fuselage

behind the receiver so it can be reached from

the back of the fuselage.

The receiver antenna should exit out the

back of the fuselage without encountering

any other wires if possible. Use a small

rubber band to hold the antenna on a T-pin

inserted in the top of the fin.

19