7

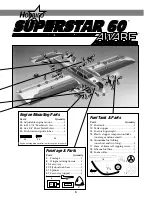

Mark the centerline on the joiner

❏

5. After the epoxy has cured and the clothespins

have been removed, draw a centerline on both sides

of the plywood

wing

joiners and the two balsa 5/16” x

1-7/16" (8mm x 36mm)

aileron

servo tray mounting

blocks. Use the plywood joiner as a template to mark

the wing

dihedral

angle on both of the balsa aileron

servo tray mounting blocks. Put these mounting

blocks aside for use in later steps.

Even the edges

❏

6. Using a flat sanding block or similar tool, sand

the wing roots so they will seat together with no gaps.

Do not sand off too much or the dihedral angle

could change.

Mark the wing cavity

❏

7. Lay the wing halves on the work surface with the

white, flat side facing up. Place a mark at the trailing

edge of the wing joiner cavity, aft of the plywood

brace on each wing half. This wing joiner locator line

will serve as a guide when cutting out the aileron

servo hole.

Trial fit the wing joiner

❏

8. Trial fit the wing joiner in

both

wings by sliding

the joiner into the joiner cavity in the wing. The joiner

should slide in with little resistance up to

the centerline.Trial fit the wing halves together. The

two panels should fit flush with no gaps.

Sand the joiner

❏

9. If the wing joiner will not fit in the cavity, lightly

sand any excess epoxy and uneven surfaces from the

joiner edges, sides and ends.

Caution: A snug fit is

desirable between the joiner and the wing cavity. Do

not sand excessively.

Viewing the wing dihedral

❏

10. Pay close attention to the orientation of the

wing joiner in relation to the dihedral of the wings

as shown.

Note: When performing the following steps 11 and 12,

be sure to use a sufficient amount of epoxy to form a

complete and solid bond between the plywood wing

joiner and the two wing halves. This is the most

important glue joint in the entire airplane.

Actual Size

Balsa Aileron Servo Tray Block (2)