Page 16

ChASSIS TUNING GUIDE

n

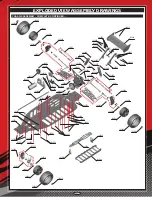

Adjusting Toe Angle - Front

It's very important when making changes to the settings of your

Outlaw RTR Brushless Buggy

that you make the settings the

same for each side. For example, if you change the spring tension on the front right shock, you should change the spring tension

on the front left shock the same amount, etc.

Chassis alignment and geometry are important if you want your

Outlaw RTR Brushless Buggy

to perform well. A good performing buggy

means a buggy that is easier to drive, too! Follow our guidelines in this section to get the most out of your

Outlaw RTR Brushless Buggy

.

Do not make any changes that are more than 3 degrees from the initial settings or the handling characteristics of your

Outlaw RTR Brushless Buggy

will become very poor.

The toe angle is the angle of both front tires (or rear tires) to each other, when viewed from above. 'Toe-in' is when the front of both tires

point toward each other and 'toe-out' is when the front of both tires point away from each other.

l

For the front tires, toe-in will make the

Outlaw RTR Brushless Buggy

track (run) straighter, but the steering will be more sensitive.

Toe-out will desensitize the steering, making the

Outlaw RTR Brushless Buggy

a little more driver-friendly.

l

Toe-in on the rear tires is fixed at approximately 2 degrees. This will give the rear end a little more 'bite' (traction).

Adding more than 3 degrees of toe-in or toe-out on the front will result in excessive loss of speed and erratic handling. Toe

adjustments should be measured with the

Outlaw RTR Brushless Buggy

at its normal ride height.

recommended initial settings

l

1 ~ 2 degrees toe-in on the front to provide stability and increase steering sensitivity. Toe-in on the rear tires is fixed at approximately

2 degrees and is not adjustable.

Straight - No Toe

Toe-In

Toe-Out

By adjusting the spring tension of the shocks, you can increase steering sensitivity, adjust the ride-height of the chassis

,

and fine-tune

the damping quality of the suspension system. How you drive your

Outlaw RTR Brushless Buggy

will dictate what settings you should

be using.

For example, if you're driving your

Outlaw RTR Brushless Buggy

off-road and going over lots of jumps, you may want to increase the

spring tension of the front shocks to help prevent the front of the

Outlaw RTR Brushless Buggy

from bottoming out. If you're racing your

Outlaw RTR Brushless Buggy

, local track conditions will dictate the settings to use.

n

Adjusting Shock Spring Tension - Front and Rear

recommended initial settings

l

We recommend initially using the preload spacers that are already installed on the shocks.

q

Increase or decrease spring tension by snapping different preload spacers onto the

shock body between the top of the shock spring and the top of the shock. Using a

taller preload spacer increases spring tension and the chassis's ride height, and will

stiffen the overall damping characteristics of the suspension. Using a shorter preload

spacer (or no preload spacer) decreases spring tension and makes the damping

characteristics of the suspension softer.

When adjusting the spring tension, make sure to adjust the right and left shocks equally.

Continued On Next Page

PRO TIP:

For more precise toe angle adjustments, use a dedicated toe angle

adjustment gauge, available at most hobby retailers.

q

To adjust the toe-angle of the front tires unsnap outer tie-rod ball end, then thread the

ball end in or out to shorten or lengthen the tie-rod. When satisfied with the result, firmly

snap the ball end back onto the ball. If more adjustment is required, the inner tie-rod

ball end can be adjusted using the same technique.

Summary of Contents for Outlaw 4WD

Page 1: ...Page 1 Kit Product 143400...

Page 37: ...Page 37 NOTES Continued On Next Page...

Page 38: ...Page 38 NOTES...