[66]

□

Step 3: T1 Wind

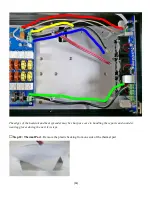

– Cut an 8” (20cm) piece of #22 Teflon wire and strip ½” (1cm) of the insulation from one

end of the wire. Insert the wire into the hole near C23 and R11 and solder the wire to the board and trim any

excess wire flush with the PCB.

Pass the wire through the holes in the core, up and back a total of 3 times. Trim the wire, strip off the insulation

and solder the wire into the hole in the PCB on the other side of C23. Trim any excess wire flush with the PCB.

You should see two wire loops on this end of the core and three loops

on the other end of the core.

When trimming the wires on the bottom of the PCB, remember to cut

them flush with the PCB, there is very little clearance between the

PCB and the copper heat spreader.

□

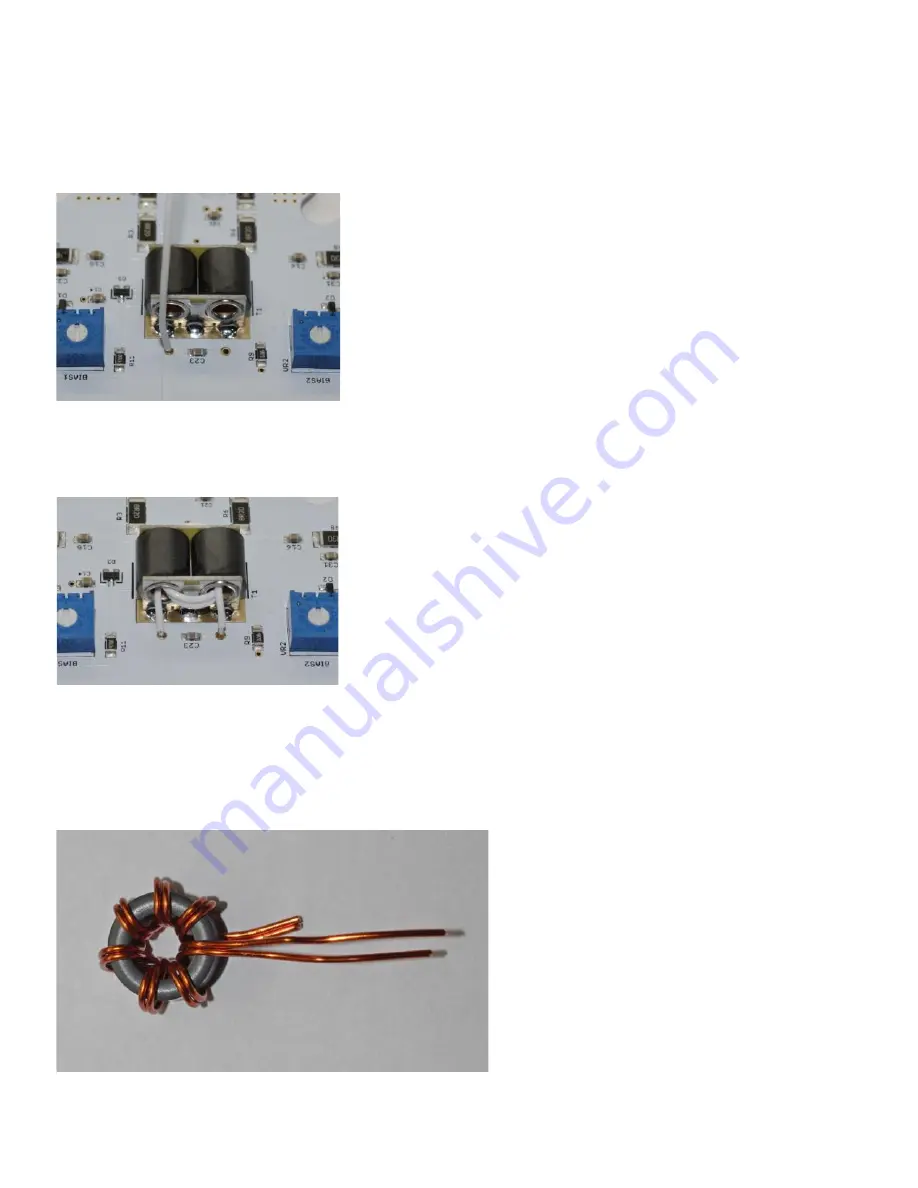

Step 4: T2 Wire Prep –

Cut two 8” (20 cm) pieces of #18 enameled wire and one 5” (13cm) piece of #22

Teflon wire. Using the #18 enameled wire wind two parallel windings of 7 turns on the Fair-rite 5961004901

core. Cut the wires about 0.5” (1cm) from the core, thoroughly scrape the wire and tin the ends with solder.