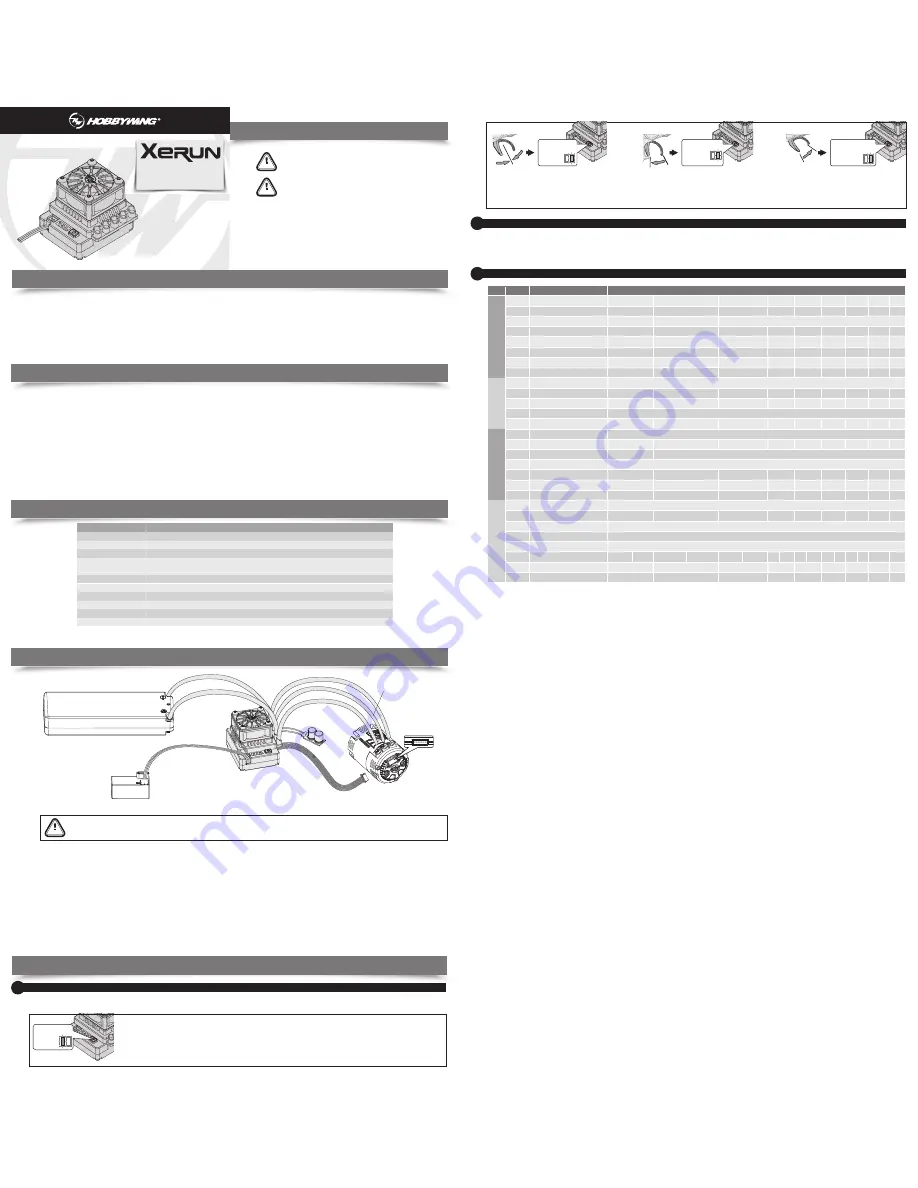

Release the

ON/OFF button

once the LED

flashes.

Item

1A

1B

1C

1D

1E

1F

1G

1H

2A

2B

2C

2D

2E

3A

3B

3C

3D

3E

3F

3G

4A

4B

4C

4D

5A

5B

5C

5D

Programmable Items

Running Mode

Max. Reverse Force

Cutoff Voltage

ESC Thermal Protection

Motor Thermal Protection

BEC Voltage

Remote Off

Sensor Mode

Throttle Rate Control

Throttle Curve

Neutral Range

Coast

PWM Drive Frequency

Drag Brake

Max. Brake Force

Initial Brake Force

Brake Rate Control

Brake Curve

Brake Frequency

Brake Control

Boost Timing

Boost Timing Activation

Boost Start RPM

Boost End RPM

Turbo Timing

Turbo Delay (sec)

Turbo Increase Rate (degree/0.1sec)

Turbo Decrease Rate (degree/0.1sec)

1-30 Adjustable (Step: 1)

0%-20% Adjustable (Step: 1%)

0%-100% Adjustable (Step: 1%)

1-20 Adjustable (Step: 1)

0-64° Adjustable (Step: 1°)

0%-50% Adjustable (Step: 1%)

3.0-11.1V Adjustable (Step:0.1V)

100%

8K

4K

37.5%

50%

62.5%

75%

87.5% 100%

12K

16K

8%

4K

25%

2K

Hybrid

Parameter Values

Forward with Brake

25%

Disabled

105

℃

/221

℉

105

℃

/221

℉

6.0V

Enabled

Full Sensored

Linear

4%

1K

0%

=Drag brake

Linear

0.5K

Linear

RPM

6

6

Instant 0.05

Forward/ Reverse with Brake

50%

Auto

125

℃

/257

℉

125

℃

/257

℉

7.4V

Disabled

Sensored/Sensorless Hybrid

Customized

6%

2K

12.5%

Customized

1K

Traditional

Auto

Forward and Reverse

75%

Disabled

Disabled

12

12

18

18

24

24

30

30

Instant

Instant

0.1 0.15

0.2 0.25

0.3 0.35

0.4 0.45

0.5 0.6 0.7 0.8

0.9

1.0

500-35000 RPM Adjustable (Step: 500RPM)

3000-60000 RPM Adjustable (Step: 500RPM)

0-64° Adjustable (Step: 1°)

Section

General Setting

Throttle Control

Brake Control

Timing

03

Features

02

Warnings

04

Specifications

05

Connections

ATTENTION

This is an extremely powerful brushless motor system. For your safety and the safety of those around you, we strongly recommend removing the pinion gear attached to

the motor before performing calibration and programming functions with this system. It is also advisable to keep the wheels in the air when you turn on the ESC.

Cont./Peak Current

Motor Type

Applications

160A/1200A

Sensored / Sensorless Brushless Motors

1/10 Touring car & Buggy competition, 1/10 drift car & F1, 1/10 & 1/8 Rock Crawler

Motor Limit

* Note 1

Model

XERUN XR10 Pro

LiPo/NiMH Cells

BEC Output

Cooling Fan

Connectors

Size/Weight

Programming Port

2-3S LiPo/4-9S NiMH

6V/7.4V Switchable, Continuous Current of 4A (Switch-mode)

Powered by the stable BEC voltage of 6V/7.2V

Input End: No Connectors; Output End: No Connectors

37.5x30.9x31.6mm (w/Fan&Fan Shroud) / 95g (w/ wires)

PRG/FAN Port (*powered by battery voltage)

Brushless Motor Limit with 2S LiPo/6S NiMH: (Touring Car) T

≥

3.5T, (Buggy) T

≥

4.5T

Brushless Motor Limit with 3S LiPo/9S NiMH: (Touring Car) T

≥

6.5T, (Buggy) T

≥

8.5T

• 10 select-to-use profiles including zero-timing/blinky mode, modified mode, stock mode applicable to all 1/10th touring car, pan car and buggy racing.

• Internal electronic key switch for

(a) long service life

(b) high reliability

(c) neat wiring.

• Built-in switch mode BEC with a maximum output of 4A and voltage adjustable between 6V and 7.4V for usage with high voltage servos.

• Separate PRG/FAN port is able to power an external fan for maximize cooling performance or connect a LCD program box or WiFi module to the ESC.

• With the New WIFI express module from Hobbywing, users are able to program parameters, upgrade firmware and check relevant data during the event using either the Iphone or

Andriod devices.

• New brakes and throttle functions: 100 levels of brag brake, 50 levels of initial brake force, 9 levels of maximum brake force, 20 levels of brake rate, and 30 levels of throttle rate.

• Adjustable brake mode, PWM and brake frequencies and for different competitions and control feel.

• Adjustable Turbo Timing & Boost Timing for different applications.

• Multiple protections: low-voltage cutoff protection, ESC and motor thermal protection, and fail safe (throttle signal loss protection).

• Data logging for recording the maximum ESC/motor temperature, motor speed/RPM, and others in real time.

• Firmware upgrade via Hobbywing multifunction LCD program box or WiFi Express (item sold separately).

• To avoid short circuits, ensure that all wires and connections must be well insulated before connecting the ESC to related devices.

• Ensure all devices are well connected to prevent poor connections and avoid damages to your electronic devices.

• Read through the manuals of all power devices and chassis and ensure the power configuration is rational before using this unit.

• Please use a soldering iron with the power of at least 60W to solder all input/output wires and connectors.

• Do not hold the vehicle in the air and rev it up to full throttle, as rubber tires can “expand” to extreme size or even crack to cause serious injury.

• Stop immediate usage once the casing of the ESC exceeds 90

℃

/194

℉

as this may cause damages to both the ESC and motor. Hobbywing recommends setting the “ESC Thermal

Protection” to 105

℃

/221

℉

(this refers to the internal temperature of the ESC).

• Users must always disconnect the batteries after use as the current on the ESC is consuming continuously if it is connected to the batteries (even if the ESC is turned off). The battery will

completely be discharged and may result in damage to the battery or ESC when it is connected for a long period of time. This WILL NOT be covered under warranty.

06

ESC Setup

ESC/Radio Calibration

1

Power On/Off

2

Programmable Items

3

Attention!

The temperature of its alunimum housing may be very high when there is heavy load. For precaution, we recommend users to have a fan blown towards the ESC.

(Start with the ESC turned off), press the ON/OFF button to turn on the ESC (the indication LED comes on); and press the ON/OFF button again to turn off the ESC (the indication LED dies out).

Note 3

:

Do not turn off the ESC when the motor is spinning. The sudden stoppage may result in unwanted damages to both the motor and ESC. If there is an emergency, battery plugs can

be pulled out to switch the ESC off.

1A. Running Mode

Option 1: Forward with Brake

Racing mode. It has only forward and brake functions.

Option 2: Forward/ Reverse with Brake

This option is known to be the “training” mode with “Forward/ Reverse with Brake” functions. Hobbywing has adopted the “DOUBLE-CLICK” method, that is your vehicle only brakes on

the 1st time you push the throttle trigger forward (brake) (1st push). The motor stops when you quickly release the throttle trigger and then re-push the trigger quickly (2nd push), only

then the vehicle will reverse. The reverse function will not work if your car does not come to a complete stop. The vehicle only reverses after the motor stops. This method is for preventing

vehicle from being accidentally reversed.

Option 3: Forward and Reverse

This mode is often used by special vehicles (rock crawler). It adopts the “SINGLE-CLICK” method. The vehicle will brake immediately when you push the throttle trigger forward (brake).

1B. Max. Reverse Force

The reverse force of the value will determine its speed. For the safety of your vehicle, we recommend using a low amount.

1C. Cutoff Voltage

Sets the voltage at which the ESC lowers or removes power to the motor in order to either keep the battery at a safe minimum voltage (for LiPo batteries). The ESC monitors the battery

voltage all the time, it will immediately reduce the power to 30% (in 3 seconds) and cut off the output 10 seconds later when the voltage goes below the cutoff threshold. The RED LED

will flash a short, single flash that repeats (

☆

,

☆

,

☆

) to indicate the low-voltage cutoff protection is activated. Please set the “Cutoff Voltage” to “Disabled” or customize this item if you

are using NiMH batteries.

Option 1: Disabled

The ESC does not cut the power off due to low voltage. We do not recommend using this option when you use any LiPo battery as you will irreversibly damage the product. You need to

select this option when you are using a NiMH pack.

Option 2: Auto

The ESC calculates the corresponding cutoff voltage as per the number of LiPo cells it detects and the “3.3V/cell” rule. For example, if the ESC detects a 2S, the cutoff voltage for the

battery shall be 6.6V.

Option 3: Customized

The customized cutoff threshold is a voltage for the whole battery pack (adjustable from 3.0V to 11.1V). Please calculate the value as per the number of LiPo cells you are using.

For example, when you use a 2S and you want the cutoff voltage for each cell is 2.8V, you will need to set this item to 5.6V.

1D. ESC Thermal Protection

The output from the ESC will be cut off with the value you have preset.

The GREEN LED flashes (

☆

,

☆

,

☆

) when the ESC temperature reaches to the preset value. The output will not resume until the ESC temperature gets down.

Warning! Please do not disable this function unless you’re in a competition. Otherwise the high temperature may damage your ESC and even your motor.

1E. Motor Thermal Protection

The GREEN LED flashes (

☆☆

,

☆☆

,

☆☆

) when the motor temperature reaches to the preset value. The output will not resume until the motor temperature gets down.

Warning!

Please do not disable this function unless you’re in a competition. Otherwise the high temperature may damage your motor and even your ESC. For non-Hobby wing motor,

the ESC may get this protection activated too early/late because of the different temperature sensor inside the motor. In this case, please disable this function and monitor the motor

temperature manually.

1F. BEC Voltage

Option 1: 6.0V

It’s applicable to ordinary servos. Do not use this option with high voltage servos; otherwise your servos may not function normally due to insufficient voltage.

Option 2: 7.4V

It’s applicable to high voltage servos. Do not use this option with ordinary servos; otherwise your servos may be burnt due to high voltage.

1G. Remote Off

Option 1: Enabled

Users can simply push and hold the brake trigger for 6 seconds. This option allows the user to turn off the ESC without pushing the ON/OFF button switch.

Option 2: Disabled

Users must turn off the ESC by pressing the ON/OFF switch button from the ESC.

1H. Sensor Mode

Option 1: Full Sensored

The power system will work in the “sensored” mode at all times. The efficiency and drivability of this mode is at the highest.

Option 2: Sensored/Sensorless Hybrid

The ESC operates the motor in sensored mode during the low-speed start-up process, followed by switching to operating the motor in the “sensorless” mode. This dual drive mode is

applicable to 4WD SCT vehicles using 4 pole motors.

Warning!

Do not select the option 1 if you are using a non-Hobbywing matching motor, when it’s a 4 pole sensored motor, otherwise you may damage your ESC and motor.

2A. Throttle Rate Control

This item is used to control the throttle response. It can be adjustable from 1 to 30 (step: 1), the lower the throttle rate, the more the limit will be on the throttle response. A suitable rate

can help driver to control his vehicle properly at the starting-up process. Generally, you can set it to a high value to have a quick throttle response if you are proficient at throttle control.

2B. Throttle Curve

The throttle curve parameter reconciles the position of the throttle trigger (in throttle zone) and the actual ESC throttle output. It is linear by default and we can change it to non-linear via

adjusting the throttle curve. For example, if adjust it to +EXP, the throttle output at the early stage will be higher (than the output when the curve is linear); if it is adjusted to –EXP,

the throttle output at the early stage will be lower (than the output when the curve is linear) and will not be as smooth.

2C. Neutral Range

As not all transmitters have the same stability at “neutral position”, please adjust this parameter as per your preference. You can adjust to a bigger value when this happens.

2D. Coast

The RPM of the motor will be lowered gradually when throttle is reduced. The vehicle will not reduce speed abruptly when the throttle is reduced to return to the neutral position.

The bigger the value, the more the “COAST” will be felt. Example, COAST of 0 deactivates, and a COAST of 20% would be the maximum amount of COAST.

1

.

Turn on the transmitter, ensure all parameters (D/R, Curve, ATL) on the throttle channel are at default (100%). For transmitter without LCD,

please turn the knob to the maximum, and the throttle “TRIM” to 0. Please also turn the corresponding knob to the neutral position.

For FutabaTM transmitter, the direction of throttle channel shall be set to “REV”, while other radio systems shall be set to “NOR”. Please ensure

the “ABS/braking function” of your transmitter must be DISABLED.

2. Start by turning on the transmitter with the ESC turned off but connected to a battery. Holding the “ON/OFF” button, the RED LED on the ESC

starts to flash (Note 2: the motor beeps at the same time), and then release the ON/OFF button immediately.

Note 2:

Beeps from the motor may be low sometimes, and you can check the LED status instead.

Press the ON/OFF button.

The Green LED flashes

three times and motor

emits “Beep-Beep-

Beep” tone.

Press the ON/OFF button.

The Green LED flashes

twice andmotor

emits “Beep-

Beep” tone.

3. Set the neutral point, the full throttle endpoint and the full brake endpoint.

• Leave transmitter at the neutral position, press the “ON/OFF” button, the RED LED dies out and the GREEN LED flashes 1 time and the motor beeps 1 time to accept the neutral position.

• Pull the throttle trigger to the full throttle position, press the “ON/OFF” button, the GREEN LED blinks 2 times and the motor beeps 2 times to accept the full throttle endpoint.

• Push the throttle trigger to the full brake position, press the “ON/OFF” button, the GREEN LED blinks 3 times and the motor beeps 3 times to accept the full brake endpoint.

4. The motor can be started 3 seconds after the ESC/Radio calibration is complete.

Move the throttle trigger

to the neutral position

Move the throttle trigger to the

end position of forward

Move the throttle trigger to the

end position of backward

Press the ON/OFF button.

The Green LED flashes

once and

motor emits

“Beep” tone.

Begin using your ESC by calibrating with your transmitter. We strongly recommend Hobbywing users to use the “Fail Safe” function on the radio system

and set (F/S) to “Output OFF” or “Neutral Position”. Example of calibrating Neutral range and Endpoint.

01

Introduction

CAUTIONS

Congratulations and thank you for your trust in Hobbywing product. By

purchasing the XERUN XR10 Pro, you have chosen a high performance

sensored brushless electronic speed controller! This speed controller is

equipped with high-tech features to enhance your experience with

Hobbywing brushless power systems. Improper usage and unauthorized

modification to our product is extremely dangerous and may damage the

product and related devices. Please take your time and read the

following instructions carefully before you start using your speed control.

We have the right to modify our product design, appearance, features

and usage requirements without notification.

ATTENTION

USER MANUAL

XERUN XR10 Pro

Brushless Electronic Speed Controller

Note 1:

The recommended T counts are only applicable with the standard 3650/540 size (3 slot 2 pole) motors when ESCs are in blinky mode.

1. Motor Wiring

The motor wiring is different between the sensored and the sensorless; please only follow the introductions below.

• Sensored Motor Wiring

There is strict wiring order from the ESC to the motor, the three A/B/C ESC wires must connect to the three A/B/C motor wires correspondingly. Next, connect the ESC sensor port and

the motor sensor port with the stock 6-pin sensor cable. If you don’t plug the sensor cable in, your ESC will still work in sensorless mode even if you’re using a sensored motor.

• Sensorless Motor Wiring

Users do not need to be worried in regards to the connectivity with the A/B/C(ESC and motor) as there is no polarity. You may find it necessary to swap two wires if the motor runs in

reverse.

2. Receiver Wiring

The throttle control cable on the ESC has to be plugged into the throttle (TH) channel on the receiver. The throttle control cable has a output voltage of 6V/7.4V to the receiver and

steering servo, hence, no separate battery can be connected to the receiver. Otherwise, your ESC may be damaged.

3. Battery Wiring

Proper polarity is essential. Please ensure positive (+) connects to positive (+), and negative (-) connects to negative (-) when plugging in the battery! When reverse polarity is applied to

the ESC from the battery, it WILL damage the ESC. This WILL NOT be covered under warranty!

Note 4:

Item 4C (Boost Start RPM) & item 4D (Boost End RPM) are not programmable if item 4B (Timing Activation) is set to “Auto”.

The PWM Drive Frequency, Brake Frequency, Brake Control, Boost Timing, Turbo Timing and relevant items are not programmable ( that's item 2E, 3F, 3G and 8 items from 4A to 5D are

not programmable) when Sensor Mode (Item 1H) is set to "Sensored/Sensorless Hybrid".

Battery

Electronic Speed Controller

Receiver

Motor

Orange (C)

Blue (A)

Sensor port of motor

Sensor wire

Yellow (B)