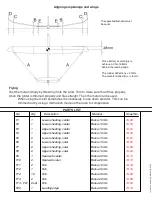

• Glue the upper sheeting F3 / F4 to the center panel.

Make sure to add glue on all ribs, the spar, the leading edge and the angled trailing edge of the lower sheeting.

Position the upper sheeting and secure it with needles and weights.

Caution

: To get a flat and straight wing, the wing center section should be left until fully cured.

The upper sheeting must be pressed at all gluing points.

• Glue the upper sheeting F7 / F8 for the outer surface parts.

Use the same procedure as used for the center panel.

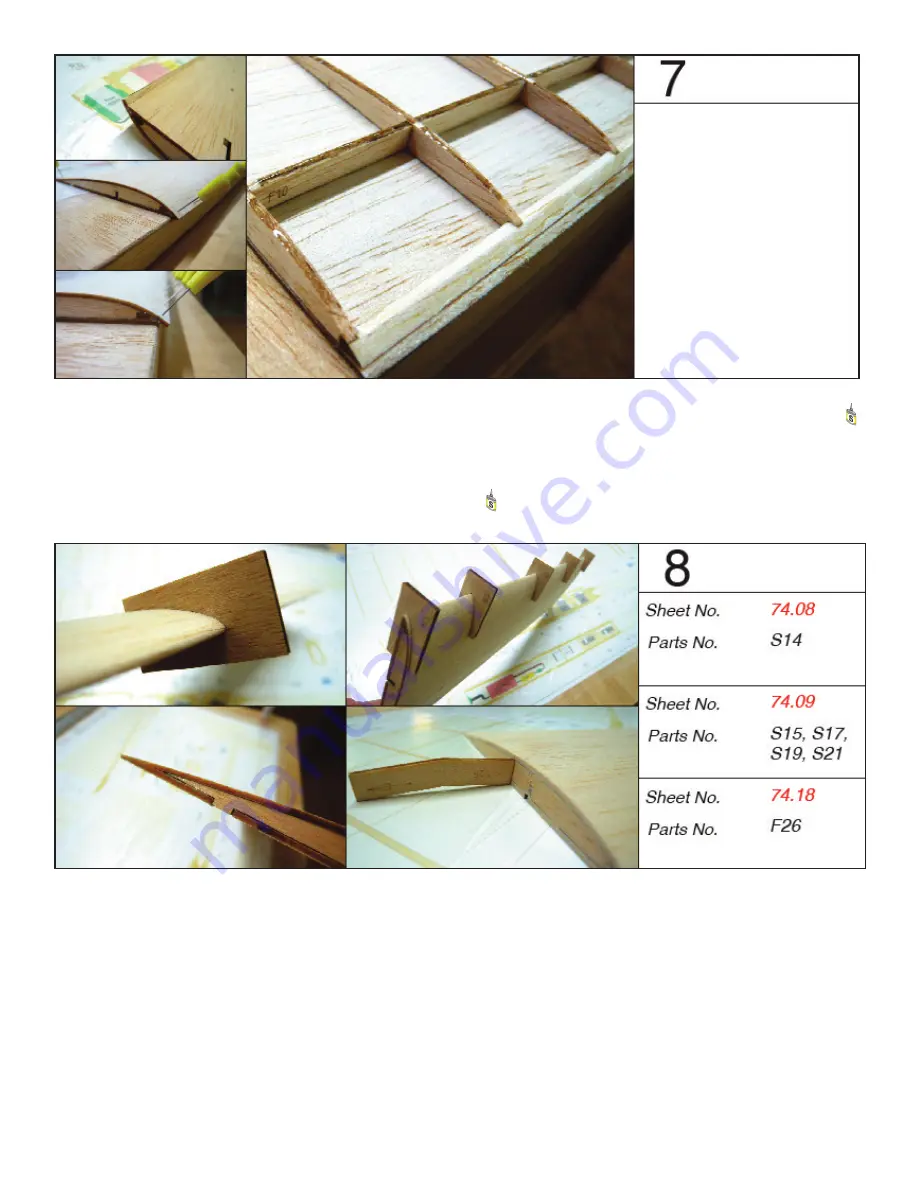

• Cut the overhanging sheeting on the leading edge and the sand the leading edge of the center part using the

stencil S14.

• Cut the overhanging sheeting on the leading edge and the sand the leading edge of the outer panels according

to the templates S15, S17, S19 and S21.

Note on positioning the templates:

template number corresponds to the rib number.

The leading edge F22 should not be visible after sanding. See also section D and E.

• Sand the sheeting at the trailing edge. (follow the airfoil)

The trailing edge should have a thickness of approx. 1mm.

• Carefully sand the sides of the middle section carefully, with the exception of the connecting ribs F14.

• Carefully sand the sides of the outer panels, with the exception of the connecting ribs F21.

Note

: To verify the V shape, the F26 joiner can be used upside down (

only to verify angle

).

In

no

va

tio

n

As

se

m

bl

y

M

an

ua

l (

EN

) V

9