46

Instruction Manual

MORSØ Notch Cutting Machine

Model NXLEH

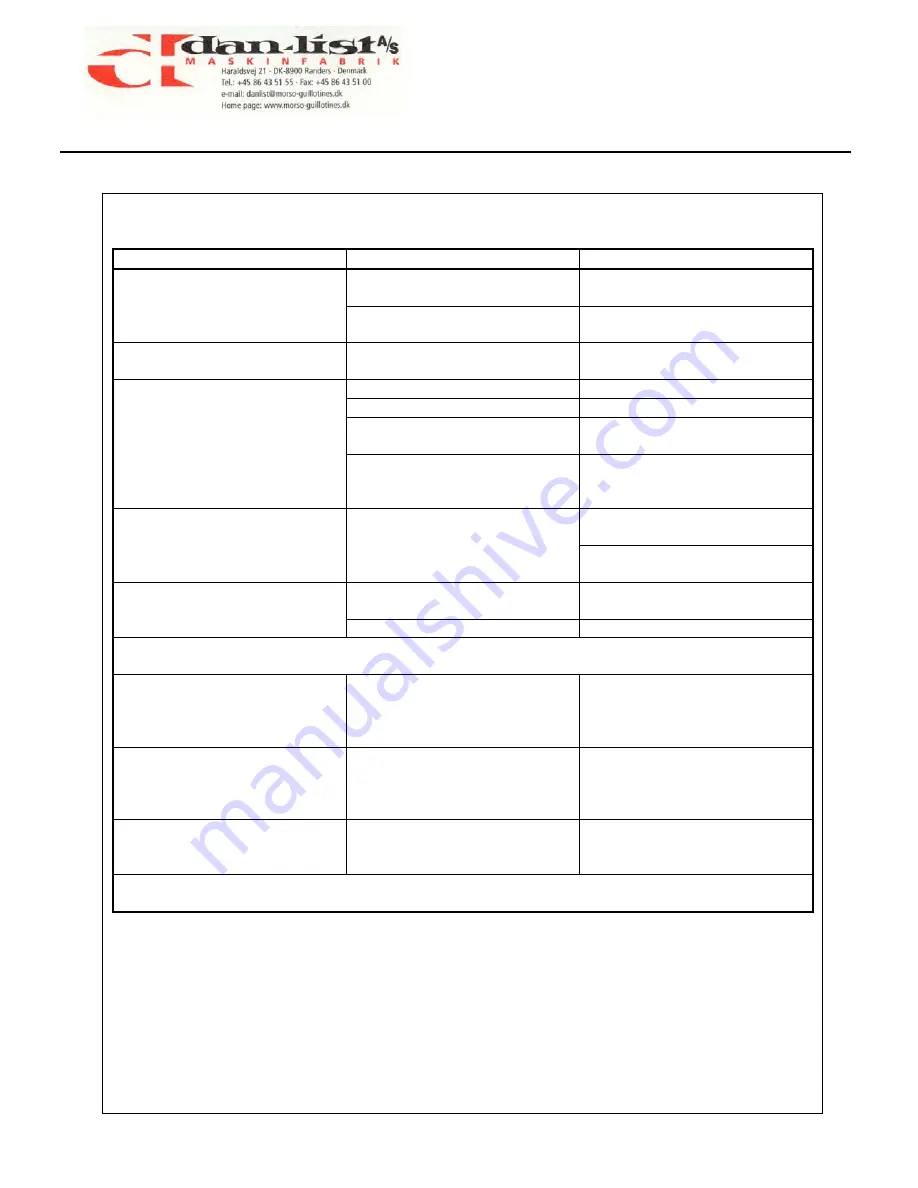

Faults Cause Repair

Incorrect cuttings

Dull Knives

Sharpen/Replace the knives

See page G-4/G-3

Knives incorrectly installed

Check the installation

See page G-3

The work piece is not firm

on the table during cutting

The Clamping cylinders

incorrectly adjusted

Correct the adjustment

See page F-7

The machine does not start

Connecting cable not connected Put the cable in the wall socket.

Connecting cable destroyed

Exchange the connecting cable

Incorrect activation of start

button

Start again

Fine fuse destroyed due to

overloading

Find out why the overloading

arises and exchange the fine

fuse

The machine stops during

cutting

Hydraulic motor over-heated

Remove the waste from the

hydraulic housing

Press the thermal cut-out on the

fitting plate

Incorrect measures

The flip stops incorrectly set

Correct the flip stop settings

See page F-6

Flip stop loose

Fasten flip stop

OBS: The clamping cylinders must always be activated (Pos. ON) for the manual

activation of the hydraulic cylinders mentioned below

Knife block does not go up or

down

Hydraulic valve not functioning

correctly

Sensor not functioning correctly

Activate manually hydraulic

valve No. 25.

See page J-6-1

Check sensor

Knife block does not go forward

or backwards

Hydraulic valve not functioning

correctly

Push buttons not functioning

correctly

Activate manually hydraulic

valve No. 26

See page J-6-1

Check push buttons

Clamping cylinders do not work Hydraulic valve not functioning

correctly

Activate manually hydraulic

valve No. 24

See page J-6-1

Should the above manual activation not solve the problem,

there might be a defect in the control system

Rectifying Faults

H-1