- 27 -

8.1.3 AUTOMATIC FLOW SENSOR CALIBRATION

1.

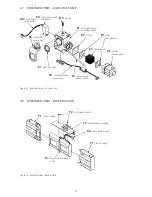

Connect the flow measurement device to the TRENDvent using the RS232 connection cable

(see Figure 15 on page 26).

2.

Connect the flow sensor, airflow resistor, adapter and TRENDvent (see Figure 15 on page 26).

3. Activate the Clinic mode.

4. Activate the Service screen using the or cursor key.

5. Select “Flow sensor calibration > automatic” using the cursor key or touch wheel.

6. Press the OK button.

7. Enter the PIN code 1302 using the cursor keys or touch wheel. Pressing the OK button

switches to the next number, respectively.

8.

The flow sensor calibration starts automatically. Pressing the esc button aborts the flow sensor

calibration.

8.2 TIGHTNESS TEST

The tightness test should be carried out as part of the annual maintenance or after the repair of rel-

evant components. The tightness test has 2 functions:

•

Testing the connected tube system and the device for leaks

•

Functional testing of the excess pressure switch

Carry out the tightness test as follows:

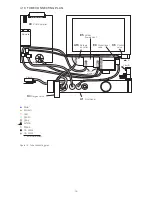

1. Seal the connection for the tube system with the blind plug APM (art-no. 0000 4831).

2. Connect the short tube of the blind plug APM to the control tube connection ( ) and the long

tube to the pressure measuring tube connection ( ).

3. Connect the device to the mains power.

4. Switch the device on.

5. Activate the Clinic mode.

6. Activate the Service screen using the or cursor key.

7. Select “Tightness test” using the cursor key or touch wheel.

8. Press the OK button.

9. Enter the PIN code 1302 using the cursor keys or touch wheel. Pressing the OK button

switches to the next number, respectively.

10.

The tightness test is started. The current pressure and current flow are displayed. The pres

-

sure is first increased to 50 hPa and a test is run to see whether the pressure at this value

stays constant for a few seconds. The pressure is subsequently increased further to 60 hPa.

If a value over 60 hPa is measured, the excess pressure switch switches the device off and an

error message for the pressure sensor is displayed in the status screen. In this case, please

contact HOFFRICHTER.

In the case of a pressure sensor error, the device must not be used.

11.

Monitor the flow value during the tightness test. At values over 3 l/min, there may be a leak in

the tube system and it should be replaced.