27

Operation manual geodyna 2350 - 9413 126

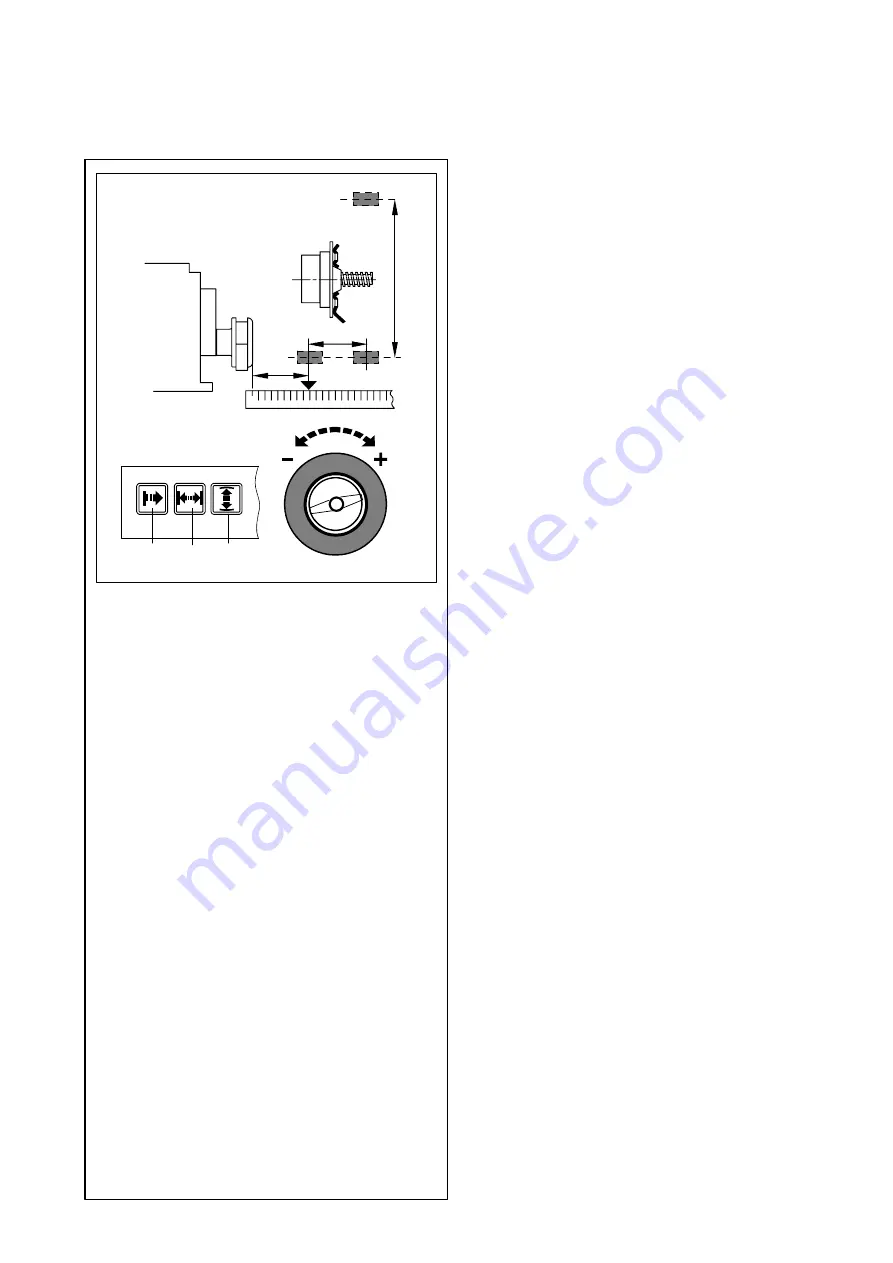

Entry of balancing mode and wheel size

49

0

1

3

2

X

7.2.7 Special balancing operations

If none of the programmable balancing modes can be used:

D

Measure the distance and the actual correction dimen-

sions (center of gravity of balance weight to be attached)

directly on the wheel

(Fig. 49)

.

D

Press and hold the key

(Fig. 49, item 1-3)

and rotate the

wheel to set the values in mm.

D

Release the key as soon as the desired value is read out.

7.2.8 Input for display of static unbalance

For wheels which should only be balanced statically, only the

correction diameter has to be entered.

Input is made as for standard wheels.

D

Press and hold the diameter key and rotate the wheel to

set the diameter values.

D

Release the key as soon as the desired value is read out.

7.2.9 Store wheel profiles

Wheel profiles permit the storage of values for wheels that are

balanced frequently so that the wheel data need not be entered

again and again. This function is particularly useful for shops

that frequently handle the same wheel types.

It is possible to store up to 4 wheel profiles via code

C18

and to

select previously stored profiles via code

C17

(see § 10.

Changing modes of operation).

The following values are stored:

-

Wheel dimensions

-

Values measured with the gauge arm

-

Weight positions

-

Positions for relocation

D

Press and hold OPERATOR key (on bottom).

RCL comes up in the left-hand section of the display and

1 comes up in the right-hand section for the first wheel

profile to be stored. Keep the key pressed on bottom and

rotate the wheel. Profiles 2 through 4 are read out in the

right-hand display. The stored wheel profile is entered

once the key is released.

If a wheel profile is to be stored, keep on pressing the key

after the RCL readings have come up and continue rotat-

ing the wheel. Now STO (store) comes up in the left-hand

display, and No. 1 through 4 can be set in the right-hand

display by rotating the wheel. The current profile is stored

once the key is released.

7.2.10 Correction of inputs after measurement

Upon operation of the FINE key the electronic unit accepts the

new input, processes it and then reads out the corrected

measured data without need to repeat the measuring run.