5

Operation manual geodyna 2350 - 9413 126

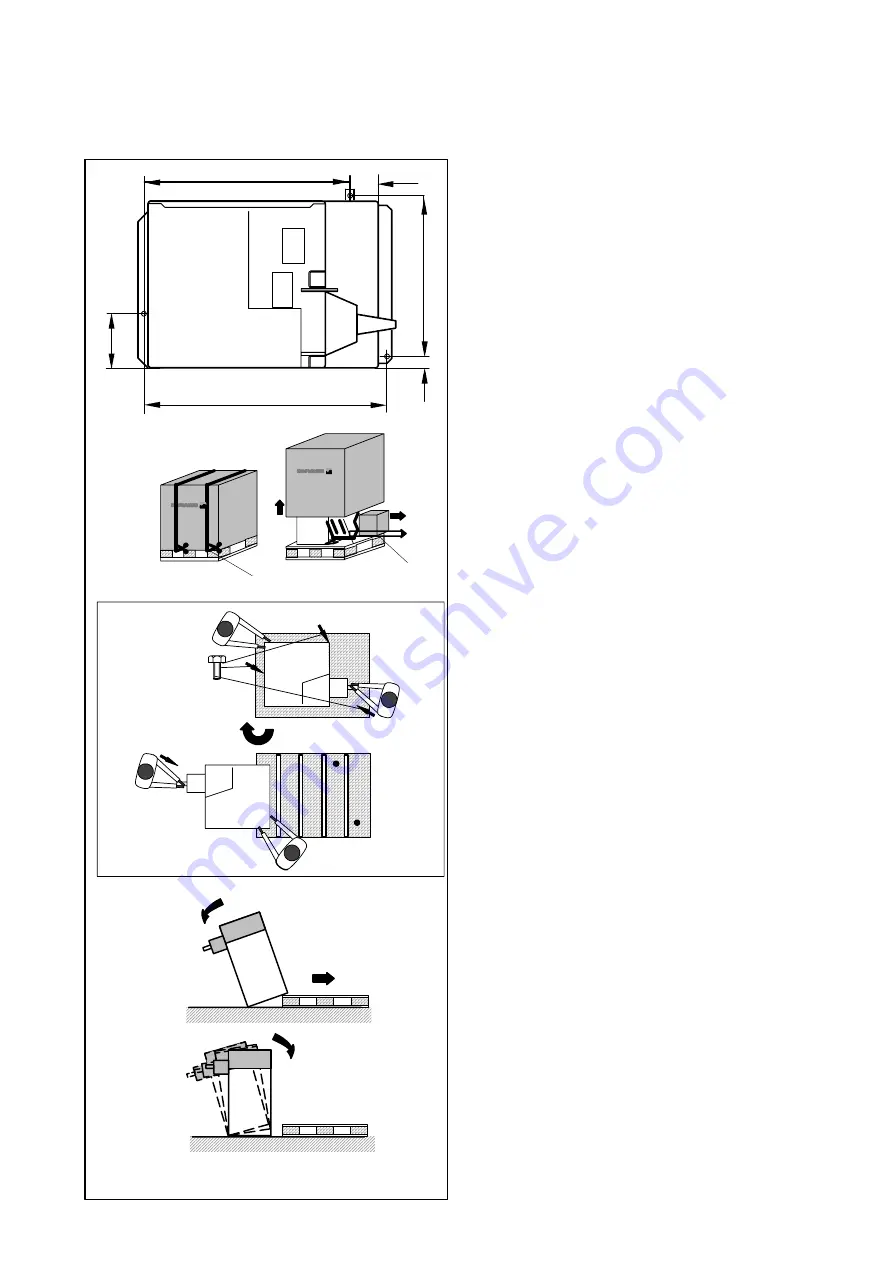

Installation of the machine

687

170

458

32

590

75

2

3

4

5

6

SW 13

1

2

2.

Installation of the machine

When choosing the site, Health and Safety at Work regulations

and the regulations on working environment should be taken

into account.

The wheel balancers can be installed on any firm and level

ground. For the weight and space requirement of the machines

refer to § 15. Technical data. For installation on an upper floor,

check and observe the permissible load capacity of the floor.

It is recommended, though not absolutely necessary, that the

machine be secured to the floor. For this purpose three holes

(Fig. 2)

are provided in the base of the machine by which the

latter is fixed on the floor with 3/8” anchor bolts. Fig. 2 shows the

center-to-center distance of the holes. Make sure that the ma-

chine has a stable position, i.e. that it is supported on

three

seatings. If not, ensure three-point contact on ground by insert-

ing appropriate spacers between the floor and machine base.

For transport the wheel balancer is provided with special pack-

ing (on pallet).

2.1

Unpacking the machine

The machine should be unpacked by two persons.

Note

When unpacking the machine make sure that the pedal fitted on

the machine base and the whole pedal assembly is not dam-

aged.

D

Cut the strips of the packing

(Fig. 3, item 1)

, lift off the

packing and set aside the small parts packed in the sep-

arate small box

(Fig. 3, item 2)

.

D

Use a 1/2” wrench to unscrew the three hexagon screws

which hold the machine on the pallet

(Fig. 4, arrows)

.

D

Lift the machine by tube of the vibratory system and turn

around by 180 degrees on the pallet

(Fig. 4)

.

D

Then lower one side of the machine laterally on the floor

(Fig. 5)

.

D

Remove the pallet from underneath the machine and

gently lower the entire machine onto the floor

(Fig. 6)

.