42

4.3-4

4.3-3

4.3-2

4.3-1

2

monty 3550

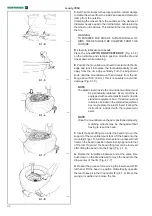

Beading with the GP device

:

The machine can be provided with a GP device, neces-

sary for bead seating of tubeless tires.

(

Figure 4.3-2

)

•

If possible lock the wheel from inside. Outside locking

reduces effi ciency of the bead seater.

•

Connect the compressed air hose to the valve (

2

).

•

Lift the tire with both hands so that upper bead is sealed

to the rim edge (

Fig. 4.3-2

).

•

Press the infl ation pedal (

1

) down swiftly. The top

bead is already sealed by the lifting motion. The air

from the bead seater jets will rebound into the bot-

tom sidewall driving it into place and creating a seal.

STOP THE COMPRESSED AIR AS SOON AS THE

BEADS GRIP THE RIM WELL.

• Place the wheel in a type approved cage to fi nish

infl ating and completely settle the beads in their seats

on the rim.

(

Figure 4.3-3

)

WARNING:

WHEN OPERATING THE BEADING DEVICE

IT IS COMPULSORY TO WEAR EAR DEFENDERS TO

PROTECTAGAINST NOISE AND SAFETY GOGGLES

TO PREVENT ANY CONTAMINATION BY DUST AND

OTHER IMPURITIES BLOWN BY THE AIR JETS.

4 . 4 M o u n t i n g a n d D e m o u n t i n g

Motorcycle Tires

To mount and demount motorcycle, motor scooter or

ATV tires it is necessary to utilize the optional adaptors

kit (EAA0329G53A) (

Figure 4.3-4

) and the small-wheel

bead breaker blade.

The bead breaking, mounting and demounting technique

is the same as per car tires.

NOTE

: If the top tire bead is diffi cult to mount, see

paragraph 4.2.1.

WARNING!

MOTORCYCLE RIMS MUST ALWAYS BE CLAMPED

FROM THE OUTSIDE.