monty 4400

Betriebsanleitung Operator’s Manual Notice d’ utilisation

Modéle :

monty 4400

_D _GB _F - Release D

HOFMANN behält sich das Recht zu Änderungen ohne Vorankündigung vor _ HOFMANN reserves the right of modification without notice _ Document non contractuel

35

4.0 CONTROLS

Before operating the machine ensure that you

have well understood the operation and function

of all the controls.

1.

To turn the machine on, rotate the ON/OFF

switch to position 1 and press the reset button:

the pump motor starts turning and remains in

operation until the machine is turned off. The

power required is minimum when the hydraulic

cylinders are not in use.

NOTE:

IT IS SUGGESTED TO TURN THE MACHINE OFF AFTER

EVERY MOUNTING OR DEMOUNTING OPERATION, IF

THE TIME BEFORE THE NEXT OPERATION IS LONGER

THAN 5 MINUTES.

2.

Press the chuck rotation pedal to the right: the

chuck rotates clockwise. Press the other pedal:

the chuck rotates counter clockwise.

3.

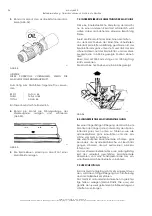

Operate the control (#1 Fig.13) to position

A

:

the chuck arm moves upwards.

Operate the control (#1 Fig.13) to position

B

: the

chuck arm moves downwards.

4.

Operate the control (#1 Fig.13) to position

C

:

the toolholder carriage moves to the right.

Operate the control (#1 Fig.13) to position

D

: the

toolholder carriage moves to the left.

758

Fig.13

5.

Operate the control (#2 Fig.13) to position

A

:

the toolholder arm moves to the right.

Turn the swich to position

B

: the toolholder arm

moves to the left.

6.

By operating the controls in one of the diagonal

positions, the two adjacent movements are

achieved simultaneously. This operation affords

considerable time saving in the intermediate

operations, but requires a little practice.

NOTE:

IF ONE OF THE TWO HYDRAULIC MOVEMENTS

REACHES THE END OF ITS COURSE, THE SPEED OF THE

OTHER MOVEMENT IS APPRECIABLY REDUCED:

INTERRUPT THE CONTROL ENGAGED AND OPERATE

ONLY THE DESIRED MOVEMENT IN ORDER TO GET

NORMAL OPERATING SPEED.

7.

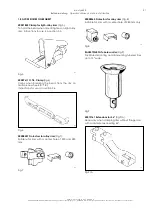

To lift the toolholder arm, depress the pedal (#1

Fig. 14) and hold handle (#2 Fig.14).

The arm is balanced by a spring-loaded mecha-

nism and the effort required is minimum.

When locking the arm into working position be sure

to use enough force to ensure a proper lock.

The heavy metal construction can easily absorb

the force.

400

Fig.14

IF THE TOOLHOLDER ARM IS NOT

CORRECTLY

LOCKED

IN

THE

WORKING POSITION SERIOUS INJURI

MAY RESULT TO THE OPERATOR AND

TO THE MACHINE.

8.

To turn the tool remove pin (#2 Fig.14).