monty 4400

Betriebsanleitung Operator’s Manual Notice d’ utilisation

Modéle :

monty 4400

_D _GB _F - Release D

HOFMANN behält sich das Recht zu Änderungen ohne Vorankündigung vor _ HOFMANN reserves the right of modification without notice _ Document non contractuel

48

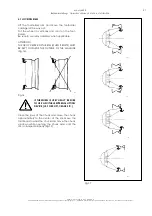

5.10 WHEEL REMOVAL

SAFE REMOVAL FOR: COMPLETE WHEEL OR RIM ONLY

1. Centre the mobile board under the wheel (or just the

rim).

2. Use the command to lower the wheel until it touches

the board. For the rim only, move it close without

touching the board.

NOTE: IF THE WHEEL IS PARTICULARLY HEAVY

USE A LIFTING DEVICE TO HOLD IT VERTICALLY.

(FORKLIFT TRUCK, HOIST, ETC.).

3. Hold the wheel in the vertical position and then

loosen the locking ring nut.

4. Remove the fixing tool, and then move outwards to

move the mobile board away from the spindle.

5. Remove the wheel by rolling or lifting from the board

with the workshop lift.

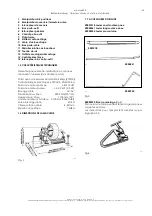

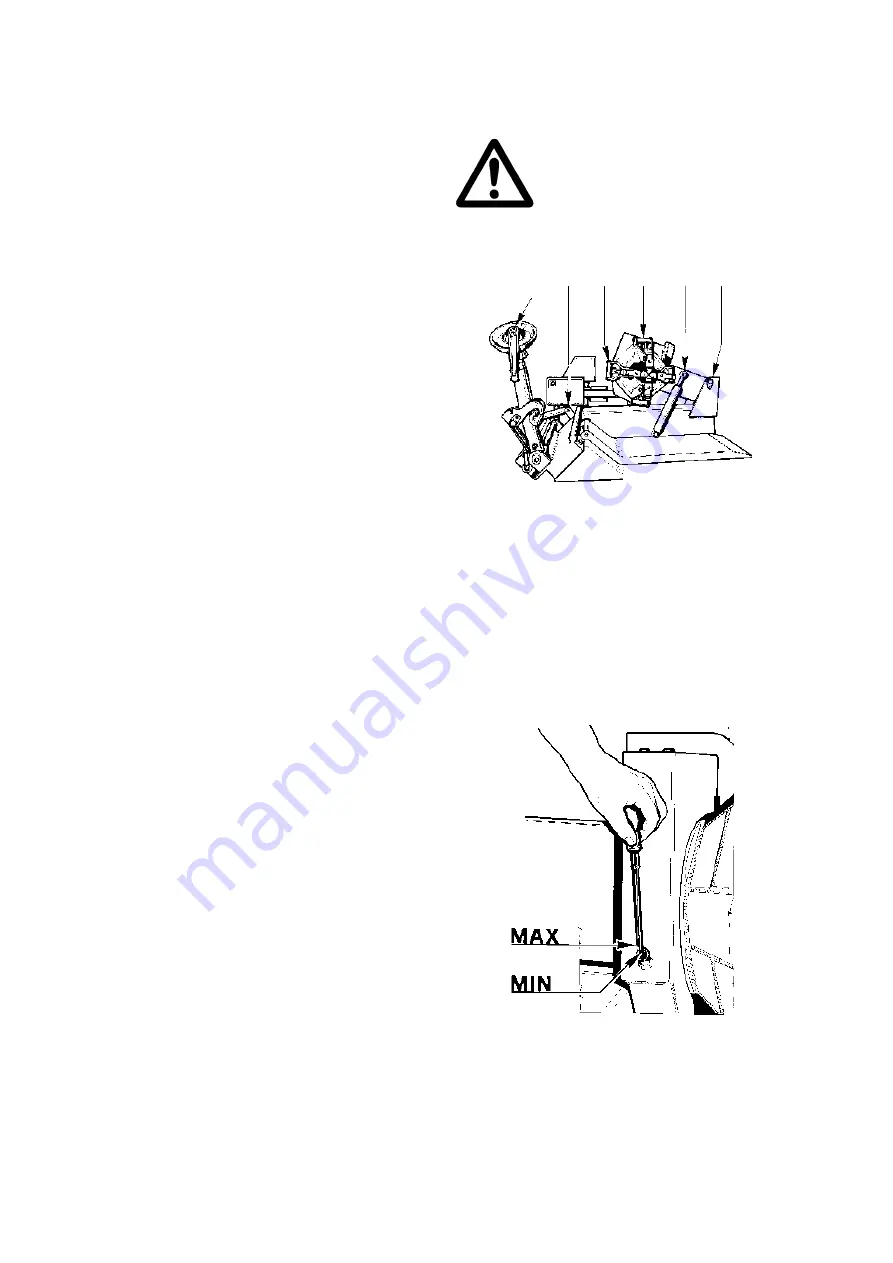

6.0 MAINTENANCE

BEFORE STARTING ANY MAINTE-

NANCE OPERATION ENSURE THAT NO

WHEEL IS MOUNTED ON THE CHUCK

AND THAT THE MACHINE IS DISCON-

NECTED FROM THE ELECTRIC SUPPLY.

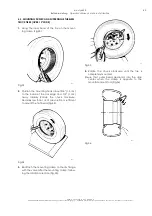

1.

Lubricate all points provided with a greasing

nipple once a month (Fig.52).

438

Fig.52

2.

Check once a month the oil level of the speed

reducer (Fig. 53). The chuck arm should be

completely lowered when the check is per-

formed.

NOTE:

THE OIL MUST BE COMPLETELY CHANGED EVERY

YEAR.

Use a synthetic lubricant for reduction units such

as:SAE 85W/90.

439

Fig.53