40

40

Stripe Hog Systems

and correct the problem before resuming blasting

operations.

Note:

A pressure switch in the charge water sup-

ply line near the UHP pump monitors charge

water pressure and automatically shuts

down the UHP system by disengaging the

OMSI Drive PTO if the charge water pres-

sure drops below 25 PSI (1.7 Bar.) This is a

safety feature to prevent damage to the UHP

pump from cavitation caused by low charge

water pressure.

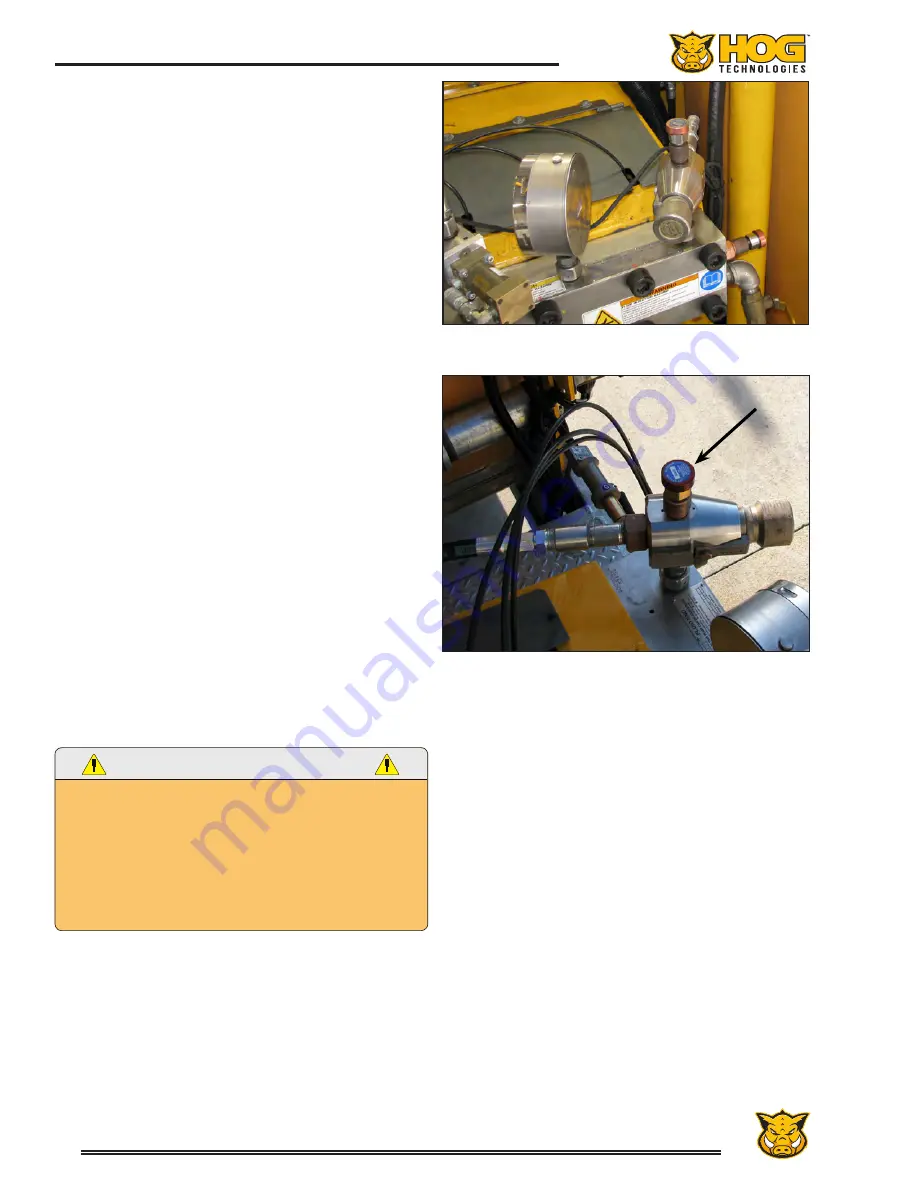

Rupture Discs

Rupture discs are installed on the high pressure

side of the UHP pump to protect the waterblasting

system against unusually high spikes in pressure.

The discs are designed to burst and immediately

relieve pressure when the system water pressure

exceeds the disc burst pressure. If a rupture disc

bursts it will have to be replaced before water-

blasting operations can resume, therefore, you

should keep spare rupture discs of the proper

pressure rating on hand. You should test the

system at low pressure and correct the problem

that caused the disc to burst before resuming high

pressure operations.

Rupture disc burst pressure ratings are unique to

each unit and critical to operator safety. Refer to

the label on the rupture disc assembly or contact

Waterblasting Customer Service for the correct

rupture disc rating for your equipment. Never

install a rupture disc with a burst pressure rating

higher than recommended.

WARNING

EXCESSIVE PRESSURE IN THE HIGH PRESSURE BLASTING

SYSTEM CAN CAUSE EXTENSIVE DAMAGE TO EQUIPMENT

AND SEVERE INJURY OR EVEN DEATH TO PERSONNEL.

IF A RUPTURE DISC BURSTS IT USUALLY INDICATES A

PROBLEM THAT NEEDS TO BE CORRECTED BEFORE

WATERBLASTING OPERATIONS CAN RESUME. NEVER

INSTALL RUPTURE DISCS WITH A HIGHER BURST RATING

THAN RECOMMENDED.

The filters in the charge pressure line immediately

before the UHP pump remove any debris prior

to the water entering the high pressure system.

These filters prevent damage caused by debris in

the high pressure system and are critical to the

proper operation of the waterblasting system.

They should be checked frequently and replaced

Rupture Discs and Manual Bypass Valve

as necessary, typically daily or when the charge

water pressure drops below 40 PSI (2.8 Bar.) Even

the smallest debris can cause severe damage to

components in the ultra high pressure system.

Refer to the Charge Water System in this section

for information on the water filters and the pump

manufacturer’s operating manual for instructions

on operating and maintaining the Ultra High Pres-

sure Pump. You should also refer to the Stripe Hog

Training video available on DVD or online at www.

stripehogsupport.com for additional instructions

on maintaining the high pressure pump.

Each manufacturer of the major UHP waterblasting

system components provides an information and

operating manual with its product. It is extremely

important that you read the manuals and become

familiar with the proper care and operation of the

components before operating the waterblasting

system.

Rupture Disk Labels

Summary of Contents for Stripe Hog SH5000

Page 1: ...Operations Manual...

Page 2: ...2...

Page 4: ...4 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 6: ...6 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 8: ...8 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 14: ...14 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 20: ...20 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 50: ...50 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 58: ...58 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 92: ...92 Component Repair THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 94: ...94 Component Repair...

Page 96: ...96 Component Repair...

Page 98: ...98 Component Repair...

Page 99: ...99 Fluid End Replacement Parts Appendix A Drawings and Supplies...

Page 100: ...100 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 104: ...104 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 106: ...106 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 110: ...110 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 118: ...118 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 121: ......