42

42

Stripe Hog Systems

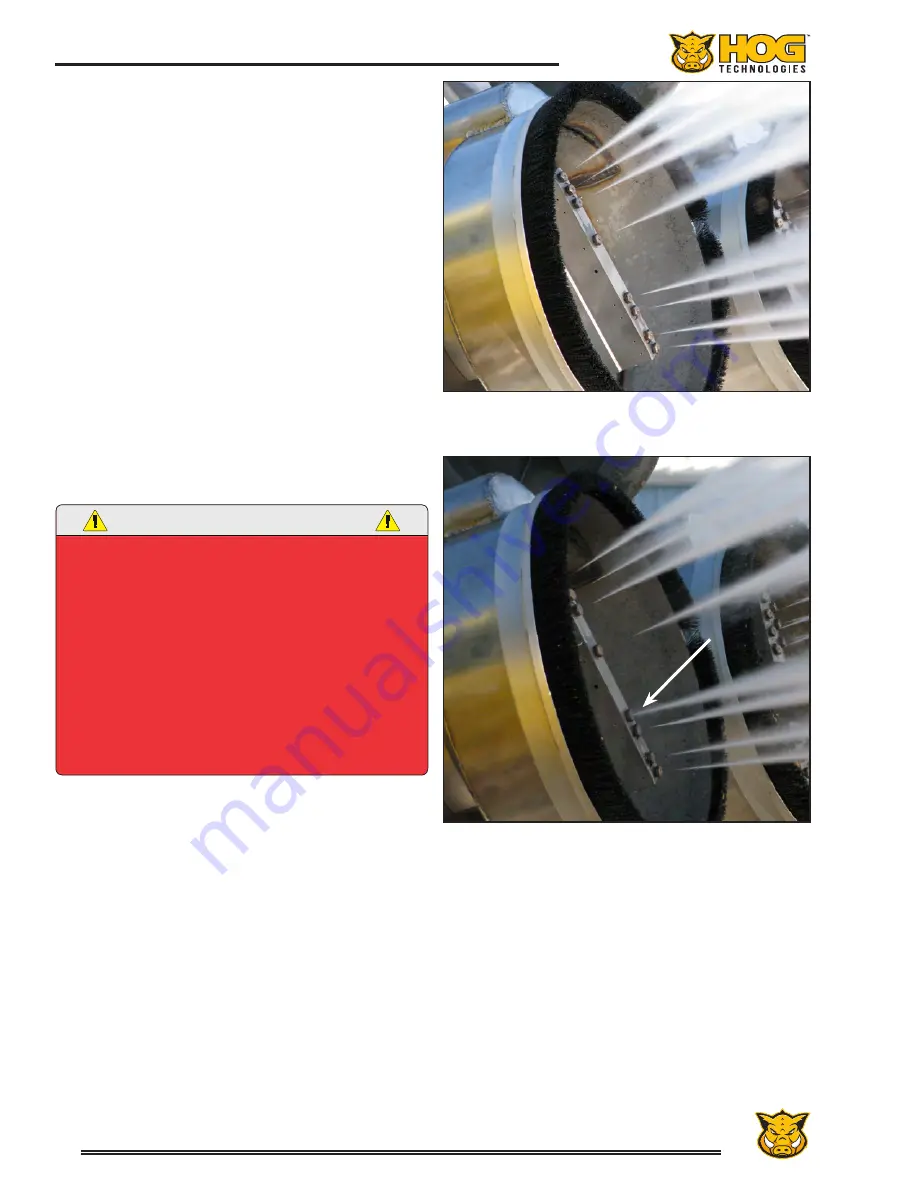

Good Nozzles

Bad Nozzle

the high pressure system and set the operating

pressure to a safe level. Make sure the head ro-

tation speed dial is set to 0 so the spray bar does

not rotate. Staying well clear of the water jets,

visually inspect the spray pattern of each nozzle.

If the spray is tight with a cohesive stream for 1/2

- 1 1/2 inches from the nozzle, it is good.

Remove Nozzle from Service if:

A) Nozzle is split or damaged;

B) Nozzle is clogged;

C) Nozzle water spray is fanned out;

D) Nozzle’s ability to hold pressure is suspect;

E) Nozzle’s hex head is worn excessively from

blasting.

F) Nozzle threads are damaged.

Refer to the Stripe Hog Training video available on

DVD or at www.stripehogsupport.com for instruc-

tions on changing nozzles.

DANGER

THE HIGH PRESSURE STREAM FROM THE SPRAY NOZZLES

CAN CAUSE SEVERE INJURY OR DEATH IF IT COMES

IN CONTACT WITH HANDS, FEET OR ANY PART OF A

PERSON’S BODY. IT CAN ALSO PROJECT LOOSE DEBRIS

IN THE AREA OF THE HOG HEAD WITH ENOUGH FORCE TO

CAUSE SERIOUS INJURY, PARTICULARLY TO THE EYES.

HIGH PRESSURE WATER CAN TEAR OFF SKIN AND INJECT

WATER DIRECTLY INTO THE BLOOD STREAM WHICH CAN

BE FATAL. ALWAYS DEACTIVATE THE HIGH PRESSURE

SYSTEM BEFORE RAISING THE HOG HEAD AND MAKE SURE

THE AREA IS CLEAR OF PEOPLE, HANDS AND FEET BEFORE

ENGAGING THE PTO AND DUMP VALVE SWITCH FOR THE

HIGH PRESSURE SYSTEM TO CHECK THE NOZZLES WITH

THE HOG HEAD RAISED.

When replacing nozzles make sure to check the

flow and pressure rating and use only nozzles with

a manufacturer’s pressure rating of at least the

pump’s operating pressure or a burst rating of no

less than 54,000 PSI (3,723 Bar.) We recommend

that you only use nozzles, high pressure hoses and

fittings supplied by Hog Technologies to ensure the

nozzles and other components are compatible with

your Ultra High Pressure Waterblasting System.

Prior to installation, make sure the nozzles have

no clogged orifices. Also, check to ensure nozzles

are sharp and not worn. To prevent galling, make

sure to apply anti-seize to the threads before in-

stalling the replacement nozzle and be careful not

to get anti-sieze on seating area of the nozzles.

Note:

To increase the life of the spray bars and

nozzles, always remember to install the

spray bar shield after testing the nozzles and

before beginning blasting operations.

Summary of Contents for Stripe Hog SH5000

Page 1: ...Operations Manual...

Page 2: ...2...

Page 4: ...4 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 6: ...6 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 8: ...8 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 14: ...14 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 20: ...20 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 50: ...50 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 58: ...58 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 92: ...92 Component Repair THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 94: ...94 Component Repair...

Page 96: ...96 Component Repair...

Page 98: ...98 Component Repair...

Page 99: ...99 Fluid End Replacement Parts Appendix A Drawings and Supplies...

Page 100: ...100 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 104: ...104 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 106: ...106 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 110: ...110 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 118: ...118 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

Page 121: ......