146

Section 5 - Scheduled Maintenance

Introduction

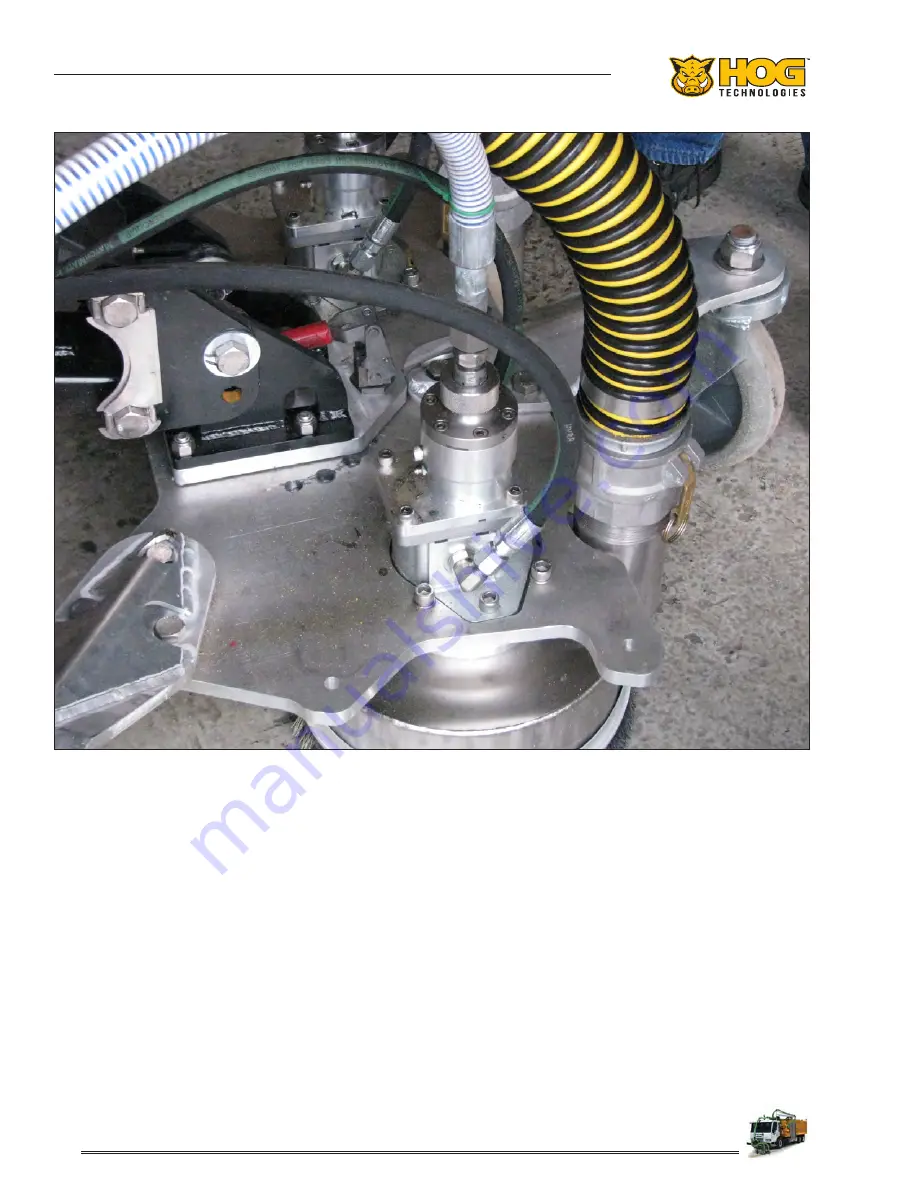

The bearing preload setting in the thru-shaft hy-

draulic motor that spins the spray head is critical

to the proper operation of the thru-shaft motor.

The bearings are carefully preset at the factory.

Then, each motor is run for several hours to break-

in the bearings and components. When break-in

is complete, the bearing preload is reset and the

motors are tested again on the truck and with

pressure applied. This normally ensures trouble

free operation of the thru-shaft motors and they

don’t require further adjustment.

Even though every effort is made at the factory

to ensure the through shaft motors are properly

broken-in and will provide trouble free operation,

there are situations where the bearing preload will

need to be reset after the truck has been operating

in the field for a period of time. Setting the bear

-

ing preload is not difficult and will not take much

time. The following instructions will guide you

through the bearing preload process and provide

the information you need to do the job properly

and in the shortest possible time.

The Instructions provide information on the tools

and materials you will need as well as the step

by step process. You can save time by reading

the instructions completely before beginning and

making sure you have all the tools and supplies

you will need readily available.

If you have any questions or require assistance,

please don’t hesitate to contact Hog Technologies

Customer Service at 772-223-7393.

5.21 Thru-Shaft Motor Bearing Pre-Load

Summary of Contents for STRIPE SH7500

Page 1: ...75 H Operations Manual...

Page 2: ......

Page 72: ...72 NOTES...

Page 108: ...108 NOTES...

Page 161: ...161 Section 5 Scheduled Maintenance...

Page 167: ...167 Appendix 2 Tools Spare Parts...

Page 168: ...168 Appendix 2 Tools Spare Parts...

Page 169: ...169 Appendix 3 Daily Report Pre Op Checklist 1 877 HOG ROAD WWW STRIPEHOGSUPPORT COM 60...

Page 178: ...178 NOTES...

Page 185: ......

Page 186: ......