32

32

Section 2 - Stripe Hog Systems

To engage the safety lock, rotate the lever toward

the cam until it rests against the cam. A spring in

the hinge will hold the lever against the cam and

automatically engage the lock lever when the Hog

Arm is raised to the full up position.

NOTICE:

To release the lock, the hydraulic system

will have to be engaged and the Hog Head

raised to relieve the strain on the lever.

Additionally, the lock lever should be se-

cured with a plastic tie wrap or other type

of fastener to ensure it cannot accidentally

release while driving if the spring fails.

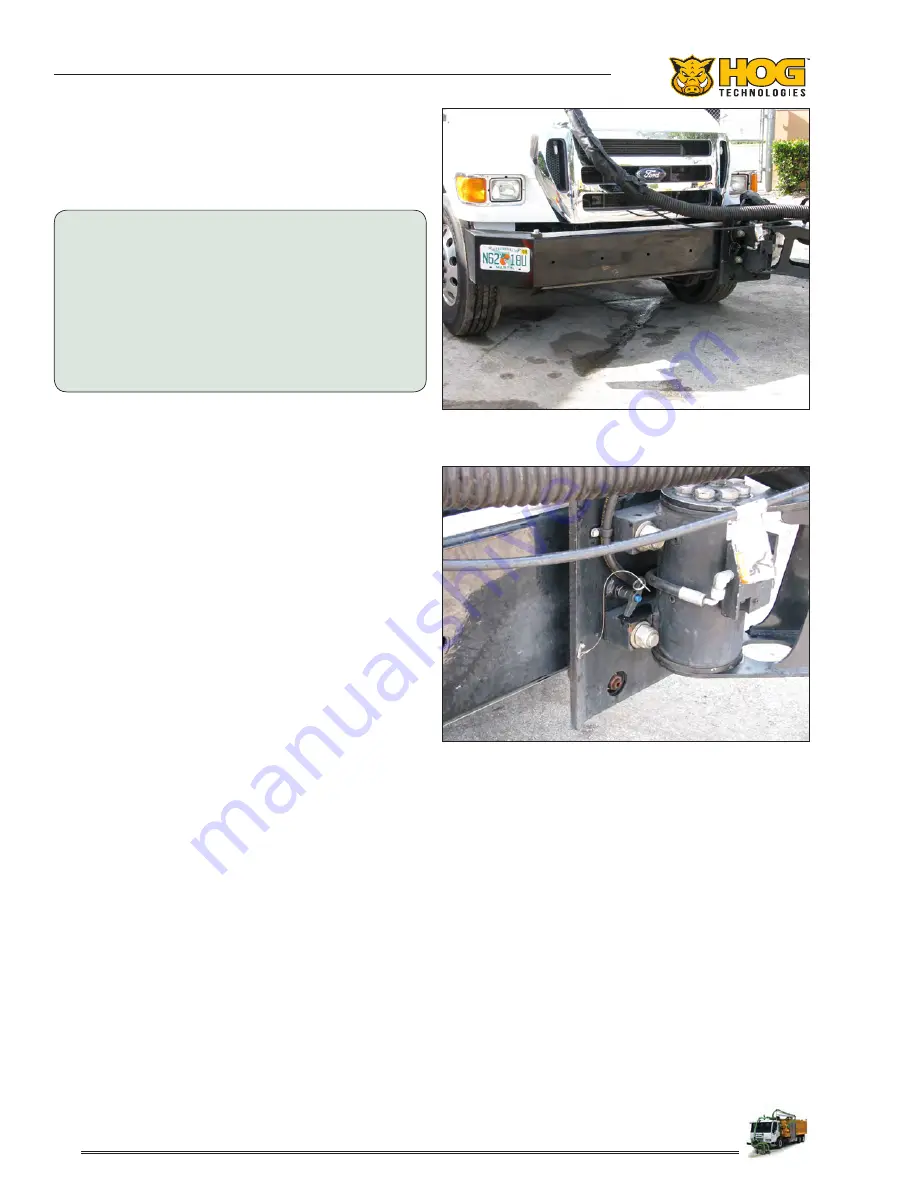

Hog Arm Slide Track (Optional)

An optional slide track Hog Arm mounting system

is an available option that enables the operator to

manually move the arm to either side of the truck

or any place in between. The Hog Arm is mounted

to a special chassis plate that rides on heavy duty

rollers and slide tracks on the front of the chassis.

A quick release T-handle lock pin secures the arm

in the selected position.

To slide the arm to a different position, lower the

arm to the full down position with the blasting

head wheels on the surface. Activate float mode

to eliminate hydraulic up or down pressure, then

remove the pin and slide the arm and blasting

head to the desired position. Secure the assembly

with the lock pin.

Refer to the Waterblasting Operation section for

additional instructions on operating the Hog Arm

slide track system.

Slide Track T-Handle Lock Pin

Hog Arm Slide Track

Summary of Contents for STRIPE SH7500

Page 1: ...75 H Operations Manual...

Page 2: ......

Page 72: ...72 NOTES...

Page 108: ...108 NOTES...

Page 161: ...161 Section 5 Scheduled Maintenance...

Page 167: ...167 Appendix 2 Tools Spare Parts...

Page 168: ...168 Appendix 2 Tools Spare Parts...

Page 169: ...169 Appendix 3 Daily Report Pre Op Checklist 1 877 HOG ROAD WWW STRIPEHOGSUPPORT COM 60...

Page 178: ...178 NOTES...

Page 185: ......

Page 186: ......