40

40

Section 2 - Stripe Hog Systems

DANGER

THE HIGH PRESSURE STREAM FROM THE SPRAY NOZZLES

CAN CAUSE SEVERE INJURY OR DEATH IF IT COMES IN

CONTACT WITH HANDS, FEET OR ANY PART OF A PERSON’S

BODY. IT CAN ALSO PROJECT LOOSE DEBRIS IN THE

AREA OF THE HOG HEAD WITH ENOUGH FORCE TO CAUSE

SERIOUS INJURY, PARTICULARLY TO THE EYES. HIGH

PRESSURE WATER CAN TEAR OFF SKIN AND INJECT WATER

DIRECTLY INTO THE BLOOD STREAM WHICH CAN BE FATAL.

ALWAYS DEACTIVATE THE HIGH PRESSURE SYSTEM BEFORE

RAISING THE HOG HEAD AND MAKE SURE THE AREA IS

CLEAR OF PEOPLE, HANDS AND FEET BEFORE ENGAGING

THE PTO, CHARGE WATER DUMP VALVE AND 40K SWITCHES

TO ACTIVATE THE HIGH PRESSURE SYSTEM TO TEST AND

INSPECT THE NOZZLES WITH THE HOG HEAD RAISED.

If a nozzle rates as a 5 or higher on the Nozzle

Quality Chart, it is worn or damaged and must be

replaced. Nozzles are easy and quick to replace.

Refer to the nozzle replacement procedure in the

Maintenance section of this manual for detailed

instructions for replacing nozzles.

Nozzles typically last 12-16 hours of blast time,

however, you can experience shorter or longer

nozzle life, depending on the source and quality of

water being used. Any dirt or debris in the system

can clog a nozzle orifice causing a spike in the high

pressure system which will rupture the burst discs

and could cause damage to components.

NOTICE:

NOZZLES MUST ALWAYS BE CHECKED WITH THE SPRAY

BAR PROTECTOR REMOVED TO AVOID INACCURATE

READINGS. START THE PUMP AT LOW PRESSURE AND

SLOWLY INCREASE TO OPERATING PRESSURE TO CHECK

NOZZLE QUALITY AND FOR LEAKS ON THE SPRAY BAR,

NOZZLES AND HOSES. SHUTDOWN THE WATERBLASTING

SYSTEM AND TRUCK ENGINE TO RELIEVE ALL WATER AND

HYDRAULIC PRESSURE BEFORE MAKING ANY REQUIRED

REPAIRS OR ADJUSTMENTS. TO INCREASE THE LIFE

EXPECTANCY OF THE SPRAY BARS AND NOZZLES, ALWAYS

REMEMBER TO INSTALL THE SPRAY BAR PROTECTORS

BEFORE RESUMING BLASTING OPERATIONS.

You can select different nozzle sizes in a variety of

spray bar configurations to accommodate the ma

-

terial to be removed and the type of substrate. The

Nozzle Quality Guide in this section and Spray Bar

Configuration Diagrams located in the Waterblast

-

ing Operation section will provide assistance in

choosing the right nozzle configurations for most

removal applications. The number of nozzles in a

spray bar should be considered in every removal

situation. The number of nozzles and the nozzle

orifice size will determine the aggressiveness of

the spray bar. As operators becomes more expe-

rienced, nozzle selection becomes easier. You can

also contact Hog Technologies Customer Support

toll free at (877) HOG-ROAD for assistance in

selecting the proper spray bar and nozzle con-

figuration for your job.

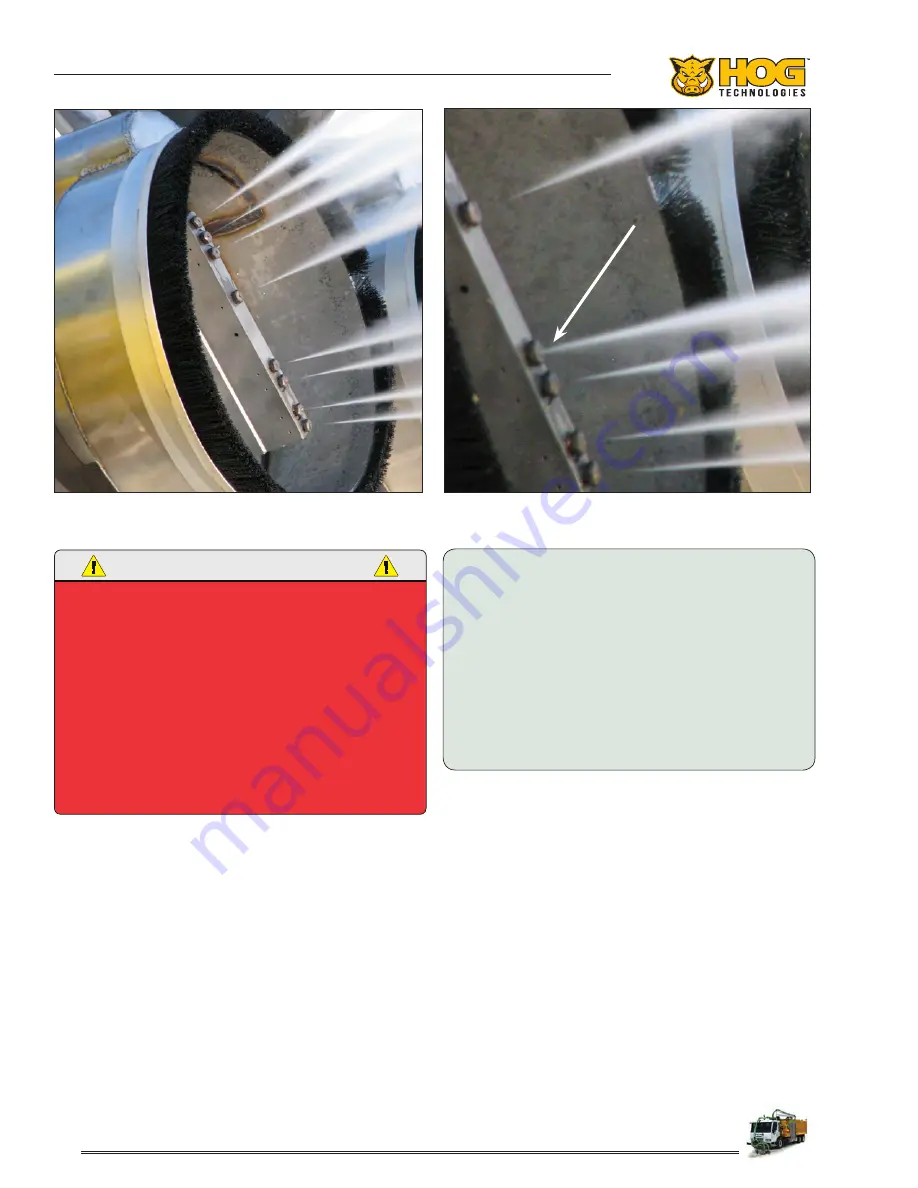

Good Nozzle Spray Pattern

Nozzles Showing Bad Spray Pattern

Nozzle Must Be Replaced

Summary of Contents for STRIPE SH7500

Page 1: ...75 H Operations Manual...

Page 2: ......

Page 72: ...72 NOTES...

Page 108: ...108 NOTES...

Page 161: ...161 Section 5 Scheduled Maintenance...

Page 167: ...167 Appendix 2 Tools Spare Parts...

Page 168: ...168 Appendix 2 Tools Spare Parts...

Page 169: ...169 Appendix 3 Daily Report Pre Op Checklist 1 877 HOG ROAD WWW STRIPEHOGSUPPORT COM 60...

Page 178: ...178 NOTES...

Page 185: ......

Page 186: ......