45

45

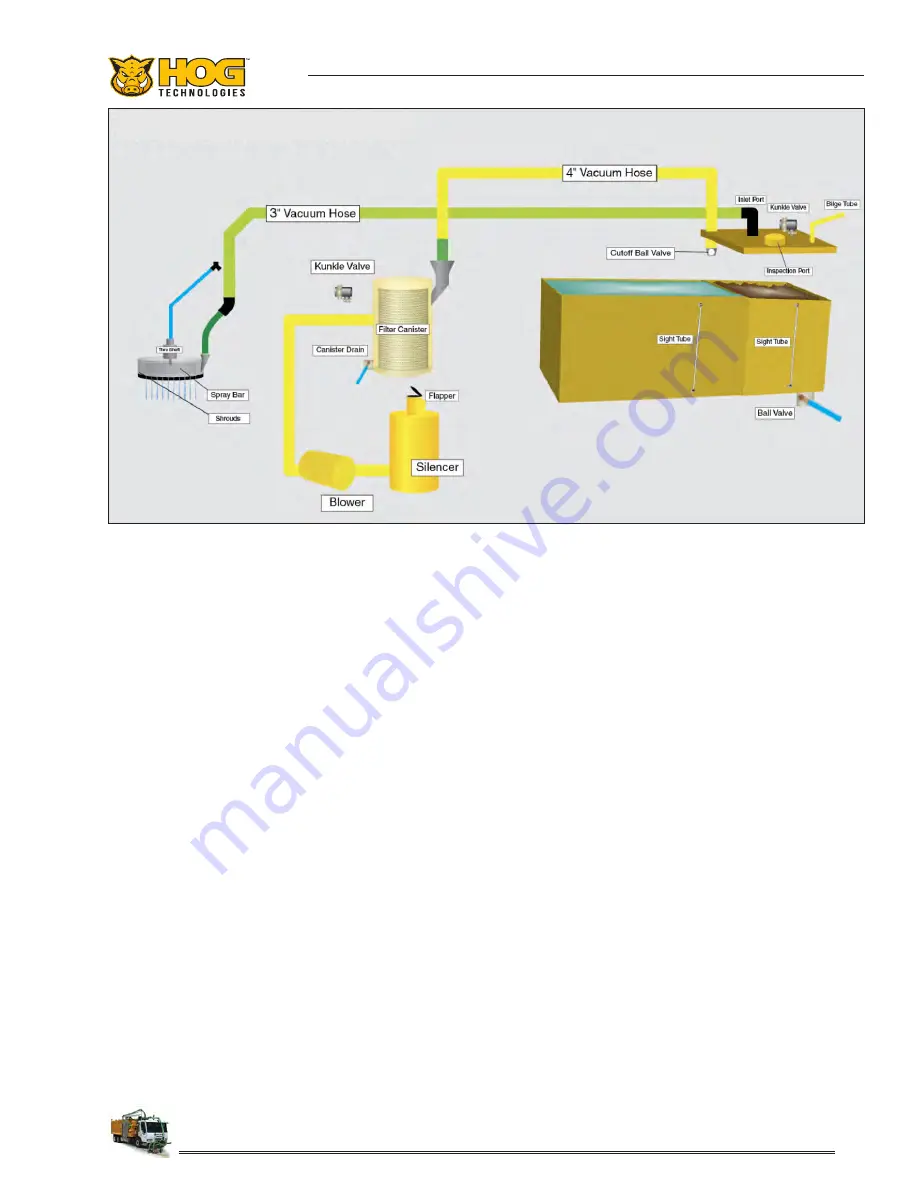

Section 2 - Stripe Hog Systems

2.7 Debris Recovery System

Overview

The vacuum system is powered by the main truck

engine and is activated whenever the OMSI Drive

PTO is engaged. The blower creates vacuum in

the filter canister, debris tank, vacuum hoses and

Hog Head. A filter located in the filter canister

protects the blower.

Flexible hoses with quick disconnect fittings pro

-

vide vacuum to the Hog Head shroud. Special

swivel brackets allow the hose to move with the

Hog Head.

The blower bearings require lubrication daily us-

ing special grease specified by the blower manu

-

facturer. Refer to the Lubrication Chart in the

Lubrication & General Maintenance section of this

manual and the blower manufacturer’s manual for

lubrication specifications or additional information

on the operation and maintenance of the blower.

The vacuum is monitored by a digital gauge in the

control panel and an optional gauge on the debris

tank. It is adjusted by increasing or decreasing

the engine RPM. Thus, maximum vacuum, -7

inHg (178 mmHg) is typically achieved at 1800

RPM (Maximum engine operating RPM). Relief

valves (Kunkle valves) on the vacuum filter can

-

ister and debris tank will automatically open if

excessive vacuum in the system occurs. Always

test the valves and all vacuum hose connections

at the start of each shift to ensure the valves are

operating properly and there are no vacuum leaks

in the system.

Blower components have extremely small toler-

ances and must be protected from the debris.

The vacuum filter should be cleaned daily. The

canister is equipped with a door in the side that

provides easy access to the filter and a means to

inspect the canister for excessive debris, water or

to clean the filter. There is a manual drain valve

at the bottom to remove water from the canister

as needed. Make sure the vacuum system is

shutdown before opening the canister door or at-

tempting to drain the water. Never leave the drain

valve open when the vacuum system is operating.

Debris Recovery System

Summary of Contents for STRIPE SH7500

Page 1: ...75 H Operations Manual...

Page 2: ......

Page 72: ...72 NOTES...

Page 108: ...108 NOTES...

Page 161: ...161 Section 5 Scheduled Maintenance...

Page 167: ...167 Appendix 2 Tools Spare Parts...

Page 168: ...168 Appendix 2 Tools Spare Parts...

Page 169: ...169 Appendix 3 Daily Report Pre Op Checklist 1 877 HOG ROAD WWW STRIPEHOGSUPPORT COM 60...

Page 178: ...178 NOTES...

Page 185: ......

Page 186: ......