66

66

Section 2 - Stripe Hog Systems

immediately and before operating the unit. A more

thorough inspection of the pump and components

should be conducted at each routine service inter-

val. Remember that the hydraulic system can be

severely damaged if it runs low on fluid.

Protect the hoses from contact with sharp objects

or kinks. Never operate the hydraulic system with

a damaged hose or a hose that is questionable.

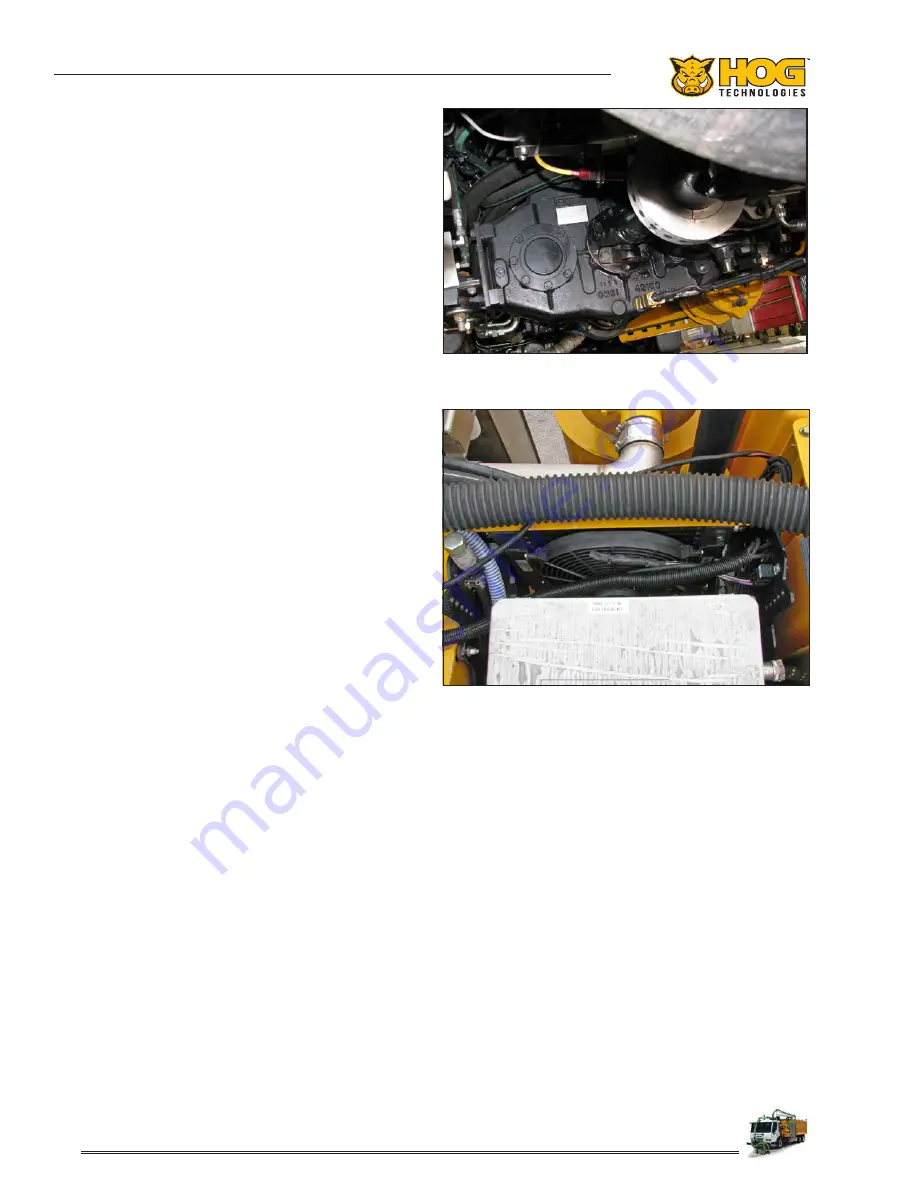

2.13 Hydrostatic Drive Hydraulic System

The Hydrostatic Drive pump is bolted to the OMSI

gearbox. It is powered by the truck engine and

primary drive shaft connecting transmission to

the OMSI drive.

The hydrostatic drive system is activated by the

PTO switch on the control panel and controlled

by the FWD/REV switch and TRUCK SPEED dial.

A swash plate controlled by the FWD/REV switch

and the TRUCK SPEED dial in the control panel

directs fluid flow and pressure output from the

pump, setting the speed and direction of the hy-

drostatic drive motor. The hydrostatic drive system

is a closed loop system that is completely isolated

from the waterblasting hydraulic system.

Hydraulic fluid is provided by the hydraulic sys

-

tem reservoir/cooling tank. A circulation pump

and a dedicated heat exchanger with cooling

fans provide continuous cooling for the hydraulic

fluid during operation. Electric solenoid valves,

activated by the FWD/REV switch and TRUCK

SPEED dial control the fluid flow in the system.

An in-line “Spin On” filter cartridge protects the

system from debris. A pressure gauge near the

filter alerts the operator when the filter is dirty

and requires changing.

2.14 Fluid Cooler Placement

The SH7500 is equipped with coolers for the en-

gine, transmission, drive train components and

hydraulic system. The coolers are located in front

of the radiator in the engine compartment, in

several locations on the chassis, behind the cab

near the high pressure pump, and on top of the

hydraulic fluid Reservoir.

The compact size of the SH7500 makes it great for

small or large jobs. It is also easy transport from

job to job and very efficient. Because the unit is

so compact, special consideration must be made

Waterblasting Hydraulic Fluid Heat Exchanger

in its design to remove heat from the waterblast-

ing and power systems. This is accomplished by

specially designed heat exchangers.

The following are the most common heat

exchangers and their function:

Engine Coolant Heat Exchanger (some models)

A rectangular shaped, plate style cooler located

behind the front bumper. Cool water from the

clean water tank is circulated through the heat

exchanger to cool the engine coolant during

operation.

Hydraulic Fluid Cooler

A heat exchanger located behind the UHP pump.

It is equipped with a fan that will run constantly

whenever the hydraulic system is activated.

Typical Omsi Drive

Summary of Contents for STRIPE SH7500

Page 1: ...75 H Operations Manual...

Page 2: ......

Page 72: ...72 NOTES...

Page 108: ...108 NOTES...

Page 161: ...161 Section 5 Scheduled Maintenance...

Page 167: ...167 Appendix 2 Tools Spare Parts...

Page 168: ...168 Appendix 2 Tools Spare Parts...

Page 169: ...169 Appendix 3 Daily Report Pre Op Checklist 1 877 HOG ROAD WWW STRIPEHOGSUPPORT COM 60...

Page 178: ...178 NOTES...

Page 185: ......

Page 186: ......