74

Section 3 - Operation

3.2 Pre-Operation Inspection

The pre-operation Inspection in this section and

the Pre-Op Check List in Appendix 4 is provided

as a guideline. Additional items should be added

to the checklist as determined by company policy,

your operating environment, and other factors

unique to your situation.

The following instructions provide a general over-

view and introduction to the pre-operation inspec-

tion. The Pre-Op Checklist provides an itemized

checklist that should be used when performing a

pre-operation inspection.

Pre-start Inspection Check List:

1. Check tire condition and air pressure.

2.

Inspect all hoses for chaffing and signs of wear.

3. Check fuel levels and make sure you have

enough for the shift.

4.

Check engine and all systems fluid levels.

Refer to the truck and OMSI Drive operating

manuals.

5. Check all waterblasting and vacuum compo-

nents for oil leaks, damaged or loose bolts

and parts.

6. Inspect the Hog Head for loose components

and damage.

7. Check vacuum canister for water and the

vacuum filter. Drain water or clean filter as

required.

8. Check the vacuum blower and UHP pump drive

belt tension and alignment.

9.

Check clean water tank level and fill if neces

-

sary.

10. Check that the wastewater bladder is empty. Drain

if necessary.

11. Drain debris tank water and check debris level.

Empty if necessary.

12. Make sure debris tank door is closed properly and

the inflatable seal pressure is correct.

13. Make sure the correct spray bar and nozzles re-

quired for the removal project are installed.

14. Visually inspect spray bars and nozzles for damage

and excessive wear.

15. Make sure all lubrication points, vacuum blower

motor bearings and Hog Head thru-shaft bearings

are greased with the specified lubricants.

16. Check all controls, switches and lights for proper

operation.

17. Make sure the Mobile Spare Parts and Tool Sys-

tems are complete and onboard.

18.

Conduct a final walk around and visually check all

components. Look for obvious problems that may

have been overlooked.

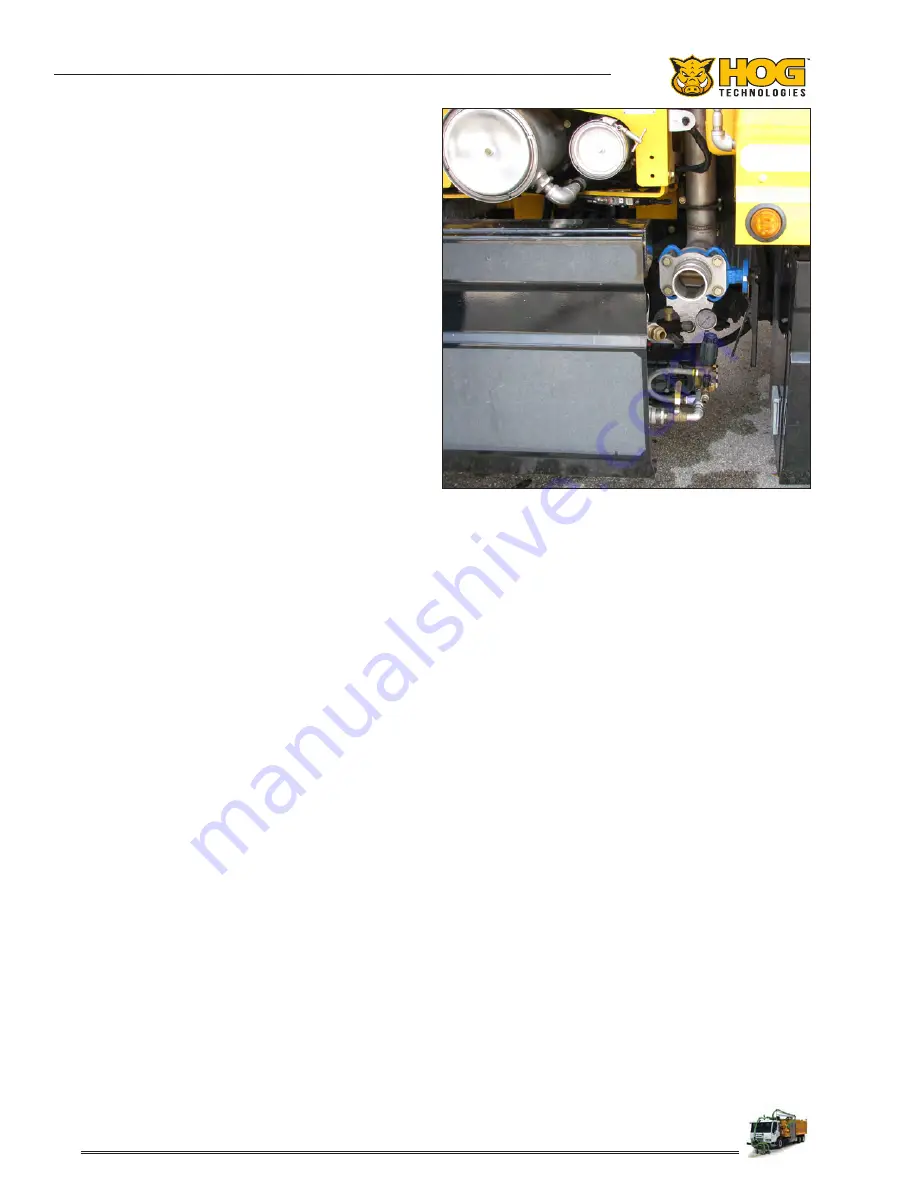

3.3 Filling The Clean Water Tank

The clean water fill connection on the passenger

side of the tank is a quick connect fitting that ac

-

commodates large hoses that are typically con-

nected to a metered source like a fire hydrant to

expedite the filling of the tank. Only use potable

water (clean enough to drink) to increase the

service life of the components in your Ultra-High

Pressure system.

Filling the freshwater tank:

1. Open the man-way on the top of the rear fresh

water tank and make sure the wastewater blad-

der is empty, then close and latch the man-way.

Clean Water Fill Fitting & Valve

Summary of Contents for STRIPE SH7500

Page 1: ...75 H Operations Manual...

Page 2: ......

Page 72: ...72 NOTES...

Page 108: ...108 NOTES...

Page 161: ...161 Section 5 Scheduled Maintenance...

Page 167: ...167 Appendix 2 Tools Spare Parts...

Page 168: ...168 Appendix 2 Tools Spare Parts...

Page 169: ...169 Appendix 3 Daily Report Pre Op Checklist 1 877 HOG ROAD WWW STRIPEHOGSUPPORT COM 60...

Page 178: ...178 NOTES...

Page 185: ......

Page 186: ......