79

Section 3 - Operation

3.6 Blasting Procedure

Overview

Before you start the job, you should evaluate the

pavement and the material to be removed. Choose

the appropriate spray bar and nozzles best suited

for the job. You should also consider the desired or

expected profile of the blasted surface in your selec

-

tion. There are many variables that affect blasting

efficiency, productivity and the profile of the blasted

surface. As operators acquire experience, the selec-

tion process becomes more refined and easier. Refer

to the visual impact guide for additional information.

Generally, large, high volume (.013 - .015) nozzles

are the most aggressive and provide faster results.

However, they also provide greater potential for

damage and a course profile. Consequently, high

volume nozzles should be used only on strong

pavement (concrete or newer pavement). Small,

low volume (.007 - .011) nozzles are less aggres-

sive and will provide somewhat slower results but

provide less potential for damage and a smoother

profile. Low volume nozzles are well suited for

weak pavement (older or damaged pavement).

Low volume nozzles are typically a better choice for

inexperienced operators on any surface.

Hog Technologies offers an on-site training program

that dramatically reduces the learning curve and in-

creases productivity. If you are new to waterblasting,

we highly recommend that you consider this factory

training for your operators. You can also contact Hog

Technologies Customer Service department for as-

sistance in choosing spray bars and nozzles or more

information regarding the factory training program.

CAUTION

THE PAVEMENT WILL BE DAMAGED IMMEDIATELY IF HIGH

PRESSURE BLASTING IS ACTIVATED WITHOUT THE HOG

HEAD MOVING. ALWAYS MAKE SURE TRUCK IS MOVING

BEFORE SUPPLYING HIGH PRESSURE TO THE BLAST HEAD.

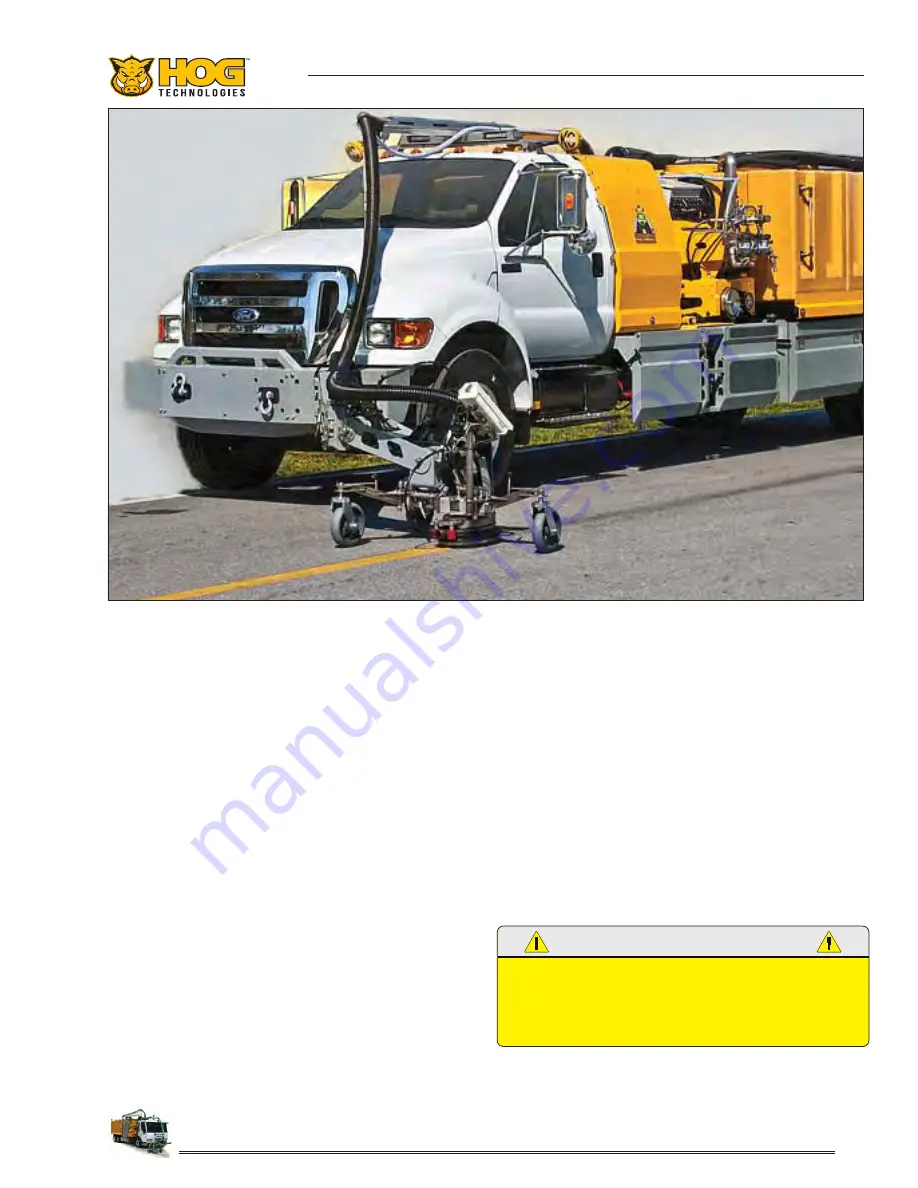

SH7500 In Operation

Summary of Contents for STRIPE SH7500

Page 1: ...75 H Operations Manual...

Page 2: ......

Page 72: ...72 NOTES...

Page 108: ...108 NOTES...

Page 161: ...161 Section 5 Scheduled Maintenance...

Page 167: ...167 Appendix 2 Tools Spare Parts...

Page 168: ...168 Appendix 2 Tools Spare Parts...

Page 169: ...169 Appendix 3 Daily Report Pre Op Checklist 1 877 HOG ROAD WWW STRIPEHOGSUPPORT COM 60...

Page 178: ...178 NOTES...

Page 185: ......

Page 186: ......