17

If the SWINGBO 2 is equipped with a wheel cover, this must be

removed before to expose visibly the two rear screws.

To do this, the marked screws must be completely removed. The wheel

cover can then be pulled out upwards.

6.3 Active degree

The active degree describes the ratio of the position of the backrest

relative to the drive wheel axis. The further the backrest is set behind

the the drive wheel axle, the more active SWINGBO 2 and 2 XL can be

driven.

SWINGBO 2 and 2 XL offer an active degree adjustment range of

level 0/1/2/3/4, each 2.5 cm

Total adjustment range is 10 cm

To adjust the active degree, remove the two screws fixing the wheel

cover and loosen the screw of the saddle clamping ring.

Setting active degree 0

The axle mount is completely extended and the rear screw connection

of the wheel cover is screwed into the rearmost hole of the frame.

This means passive driving.

Setting active degree 1

The axle mount is not completely extended and the rear screw

connection of the wheel cover is screwed into the penultimate hole of

the frame.

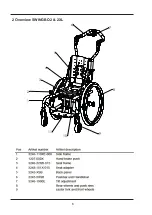

Summary of Contents for SWINGBO 2

Page 1: ...en SWINGBO 2 2XL Service instructions...

Page 6: ...6 2 Overview SWINGBO 2 2XL 1 2 4 5 6 7 8 9 3 11 10...

Page 39: ...39...