A S S E M B LY

I N S T R U C T I O N S

F R A M E A S S E M B L Y

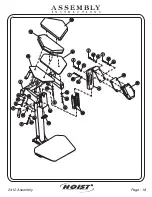

Step 2f

FITNESS SYSTEMS

R

HOIST

In this step start by sliding one (30) on both handles on (6). Then,

slide on one (31) on each side. Place (29) on the end of the handle. Once

all three pieces (per side) are in place, secure (29), slide (31) flush with

(29) and secure. Insert all (28) as shown.

screws.

Allen Wrench tighten

6 - Arm Rest Assy.

28 - 2” x 3” End Cap (VH)

29 - 1 1/4” Dia. X 3/4” Aluminum Cap

30 - 1 1/4” Dia. X 3/4” Aluminum Ring

Part Descriptions

L - #10-32 Set Screw

Hardware Descriptions

2412 Assembly

Page 15