6

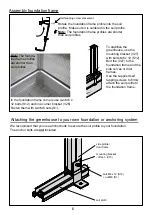

Note: The founda-

tion frame profiles

are shorter than

soil profiles

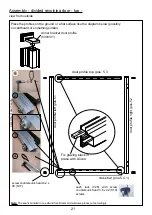

Attaching the greenhouse to your own foundation or anchoring system

We recommend that you use anchor bolts to

secure the soil profile to your foundation.

The anchor bolts are

not

included.

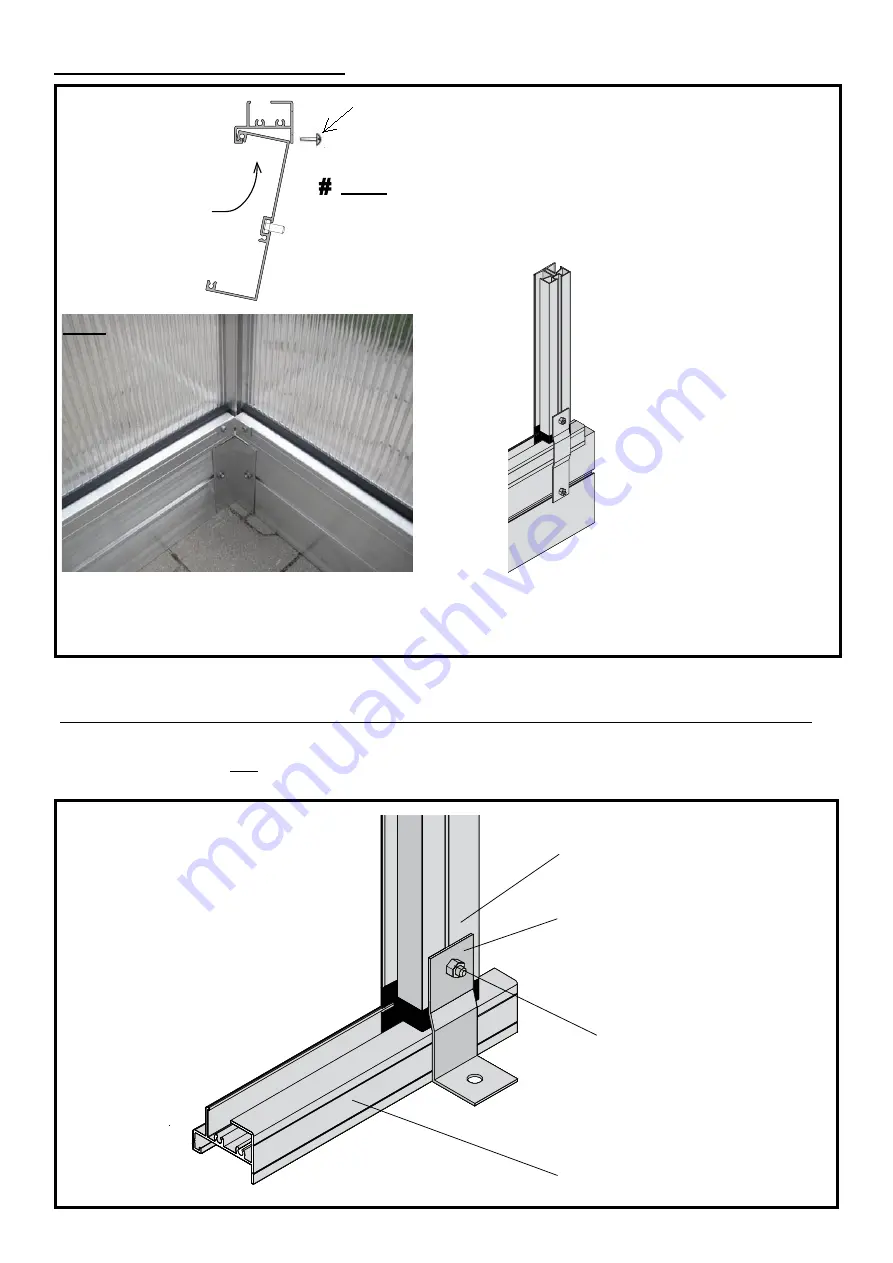

side profile/

door frame

mounting bracket

- offset - (V

5)

bolt M6 x

2 (S

2)

+ nut M6 (S

)

soil profil

Rotate the foundation frame profile into the soil

profile. Make sure it is centered in the soil profile.

N

ote:

The foundation frame profiles are shorter

than soil profiles

To stabilize the

greenhouse, use the

mounting bracket (V27)

with

bolts M6 x 2 (S2)

Bolt the (V27) to the

foundation frame and the

side curves or door

frames.

Use the supplied self

tapping screws to firmly

attach the soil profile to

the foundation frame.

In the foundation frame corners use two M6 x

2

bolts

(S2)

and one corner bracket (V26)

Fasten them with two M6 nuts

(S).

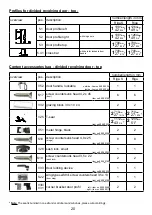

Assembly foundation frame

Self-tapping screw placement