BA_PH_245-20_EN_15-22.docx

34

12

Tool Change

12.1

With Quick Clamping Device (Standard)

The tools used on the machine must comply with EN 847-1!

Wear cut-resistant protective gloves when changing tools!

•

Before changing the tool, switch off the spindle drive with the button (see

Then wait approx. 15 seconds

→

The motor brake opens automatically

•

Now turn the spindle by hand so that the clamping screw (

C

) is accessible (see

•

Press one of the two emergency stop buttons (

4

) and leave it locked.

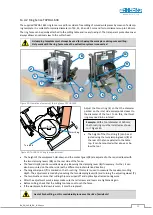

Figure 15: Milling arbor with quick clamping device

1.

Loosen the clamping screw (

C

) on the quick-re-

lease nut (

M

) with the supplied SW4 pin spanner.

2.

Then fully tighten the fixing

screw (

F

) by hand and remove

the quick-release nut (

M

) by

taking it out.

3.

Remove the spacer rings (

D

)

and put on the new cutter head.

Ensure that the clamping surfaces of the

spacer rings and clamping nut are clean.

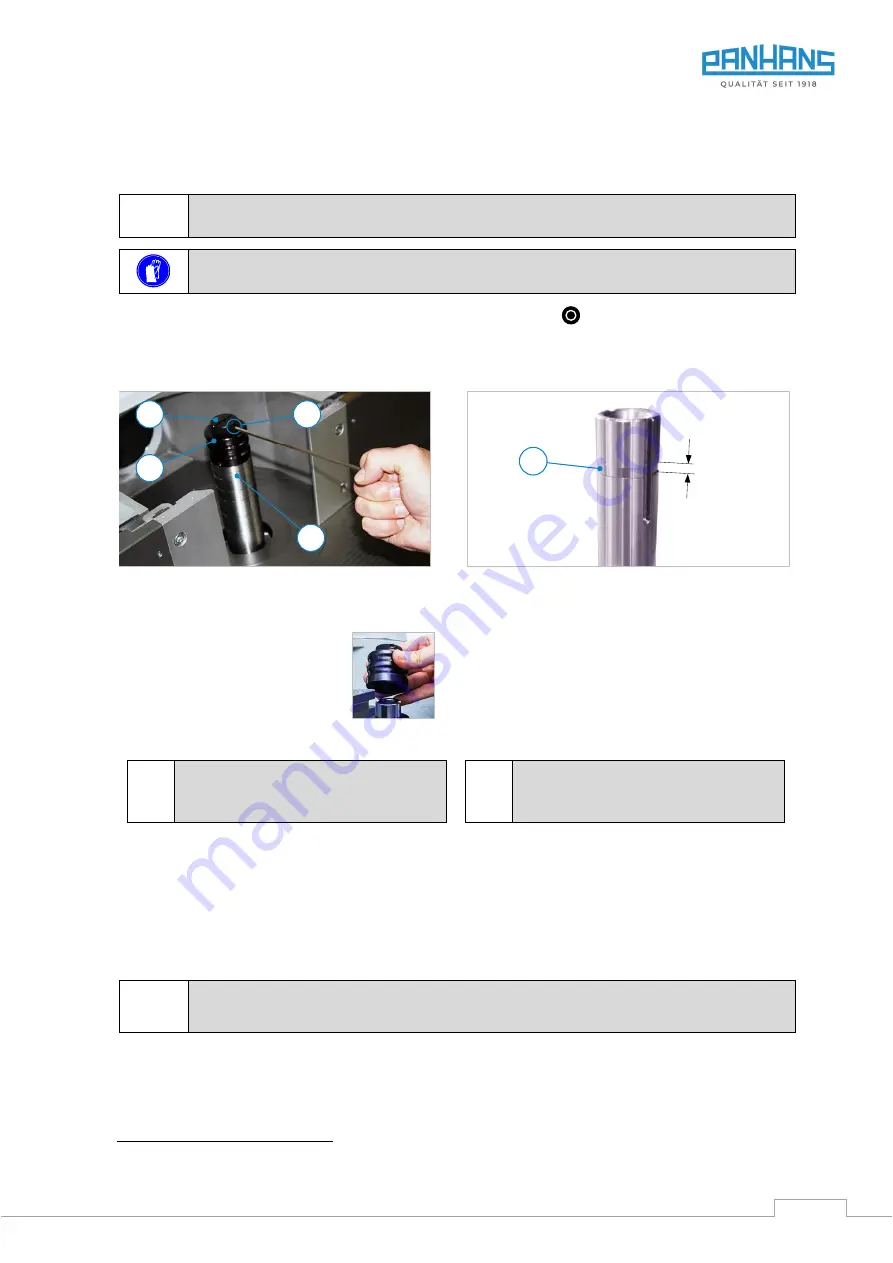

Figure 16: Marking for upper spacer ring

4.

Put on the required spacer rings (

D

), if necessary.

Place enough spacer rings so that the upper

clamping surface of the upper ring is in the area

(

E

) of the marking groove shown in

5.

Then put the quick-release nut (

M

) back on and

tighten the fixing screw (

F

) by hand.

6.

Now tighten the clamping screw (

C

) with the SW4

pin spanner

→

Tightening torque =

12 Nm

.

With 12 Nm tightening torque of the

clamping screw (C), the cutter is clamped

with approx. 30 KN (= 3 t).

•

After the tool change, unlock the emergency stop button (

4

) again

.

12.2

With HSK 80 Tool Changing System (Option)

Instead of the rigid 30 mm milling spindle fitted as standard, the optional HSK 80 quick-change system uses a

milling arbor

2

(Ø 30 mm) with spindle locking device. This allows a quick and convenient tool change of the com-

plete milling arbor. The supplied SW8 pin spanner (with lateral magnet) is required for the exchange procedure.

The condition of the tool spanner must be checked occasionally. Using a pin spanner with

worn edges can lead to the destruction of the clamping cartridge.

2

Milling arbors with diameters of 35, 40 and 50 mm as well as 1¼" are also optionally available (see

0).

C

F

M

D

E