BA_PH_245-20_EN_15-22.docx

54

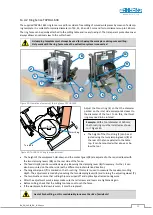

16.9.3

Adaptation to the Machine Table (only required for retrofitting)

ca. 275

ca. 300

440

Fräsdorn

Tischplatte

=

=

M12

M12

Figure 53: Adapt tenoning device (drilling sketch)

Mount the tenoning and slotting

device as close as possible to the

milling arbor.

The diameters of the largest and

smallest cutter heads used are deci-

sive for the distance to the milling

arbor.

•

Place the tenoning device on

the machine table (parallel to

the table edge).

•

Determine the distance to the

milling arbor and mark the cen-

tre of the crossed slotted holes

on the table top.

We recommend drilling the holes according to the sketch above, whereby the dimension 275 mm depends on

the cutter head diameter used.

•

For this purpose, two M12 threads must be fitted (bore diameter = 10.2 mm).

•

Fasten the tenoning device with M12 x 30 hexagon screws and washers.

16.9.4

Supplementary Protective Cover 1641 (Option)

The protective cover type 1641, also shown in

Figure 51, is an ideal complement to the tenoning and slotting

device type 1376. It is suitable for tenon cutting and slotted discs up to max. 350 mm. The cover is made of strong

sheet steel and has an adjustable protective hood as well as an extraction nozzle with an outer diameter of 120

mm. For article number see section

16.10

Kickback Guard Type 1648

Figure 54: Kickback guard type 1648

The kickback guard type 1648 is used for acci-

dent-free insertion milling of long and short

parts in combination with the optional table

extension.

It is infinitely adjustable from 0 to 1500 mm

and intuitive to operate.

Article number see section

Milling arbor

Table top

approx. 300

approx. 275