BA_PH_245-20_EN_15-22.docx

56

16.13

Power Feeders

For safety reasons, a power feeder should be used whenever possible.

Generally applies:

Always adjust the power feeder so that the workpiece is guided safely along the fence. Set

the unit at an angle of approx. 5° to the feed direction and keep the opening to the fence as small as possible.

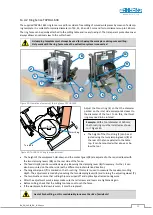

Figure 57: Power feeder type PV84

Figure 58: Power feeder type Variomatic 4N

•

Power feeder with 4 rollers (120 x 60 mm)

•

8 adjustable feeding speeds

(2/4/5,6/6,7/11/13/16,5/33 m/min)

•

Clockwise/anti-clockwise rotation

•

Stand with an max. outreach of 1,050 mm

by an elongated extension arm

•

Metal gearbox for setting four additional speeds

•

Can be used individually horizontally and vertically

•

incl. mounting, cable and plug

•

Power feeder with 4 rollers,

•

Infinitely variable feed speed from 2 - 18 m/min

as well as clockwise/anti-clockwise rotation

•

Rotate to insert horizontal/vertical.

•

Max. outreach of 1,050 mm

•

Easy swivelling away and positioning with

memory lock system.

•

With comfort stand and numerical height display

•

incl. mounting, cable and plug

Both models are supplied with 400 volts and can be connected to the existing machine socket. For further infor-

mation on operation and functionality, please refer to the separately enclosed

Operating manual of the cor-

responding manufacturer

.

The article numbers can be found in the section

16.13.1

Consoles for Power Feeders

Figure 59: Console rigid

Figure 60: Console movable

Rigid add-on console for a power feeder. The platform

(approx. 195 x 180 mm) is mounted on the left side of

the table top.

Movable add-on console for a power feeder. The unit

is mounted on the left side of the machine column and

has a joint for swivelling away the feed unit.

The article numbers can be found in the section