BA_PH_245-20_EN_15-22.docx

58

18

Maintenance and Inspection

Before any maintenance and inspection work is carried out, chapter

4 "Safety"

must be read carefully and observed!

Operational malfunctions caused by insufficient or improper maintenance can result in very high repair costs and

long machine downtimes. Regular maintenance is therefore essential.

•

Clean the machine daily.

•

Check all sliding or rolling parts weekly for smooth running and lubricate with a thin-bodied oil if necessary.

•

Inspect electrical equipment/components weekly for externally visible damage and have them repaired by

a qualified electrician if necessary.

•

Immediately remove and replace damaged guards. Never work with damaged equipment!

•

Before starting work, check the extraction system for full function every day.

•

The extraction system must be checked for obvious defects before initial commissioning, daily and monthly

to ensure its effectiveness.

•

The air velocity to the extraction system must be checked before the initial commissioning and after signifi-

cant modification.

•

If the motor no longer brakes within 10 seconds when switching off, it is essential to contact the customer

service.

•

Do not use the machine until these conditions are met.

Due to the different operating conditions, it is not possible to determine in advance how often a wear check,

inspection or maintenance is required. Inspection intervals are to be determined appropriately according to the

respective operating conditions.

Please also read section

“Maintenance Plan”.

18.1

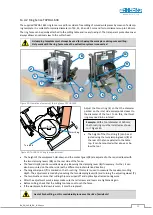

Maintenance of the Milling Fence

The milling fence should be cleaned thoroughly at regular intervals. The contact surfaces between the milling

fence and the fence plates and between the milling fence and the table top are particularly important. Dust can

accumulate at these points. This can lead to inaccuracies when positioning the milling fence.

18.2

Maintenance of the Tenoning and Slotting Device Type 1376 (Option)

Regularly clean all moving parts from dust and dirt and lubricate with a thin-bodied oil. If the tenoning and slot-

ting device is not used for a longer period of time, the bare parts should be covered with a light film of oil to

protect them from corrosion.