BA_PH_245-20_EN_15-22.docx

59

18.3

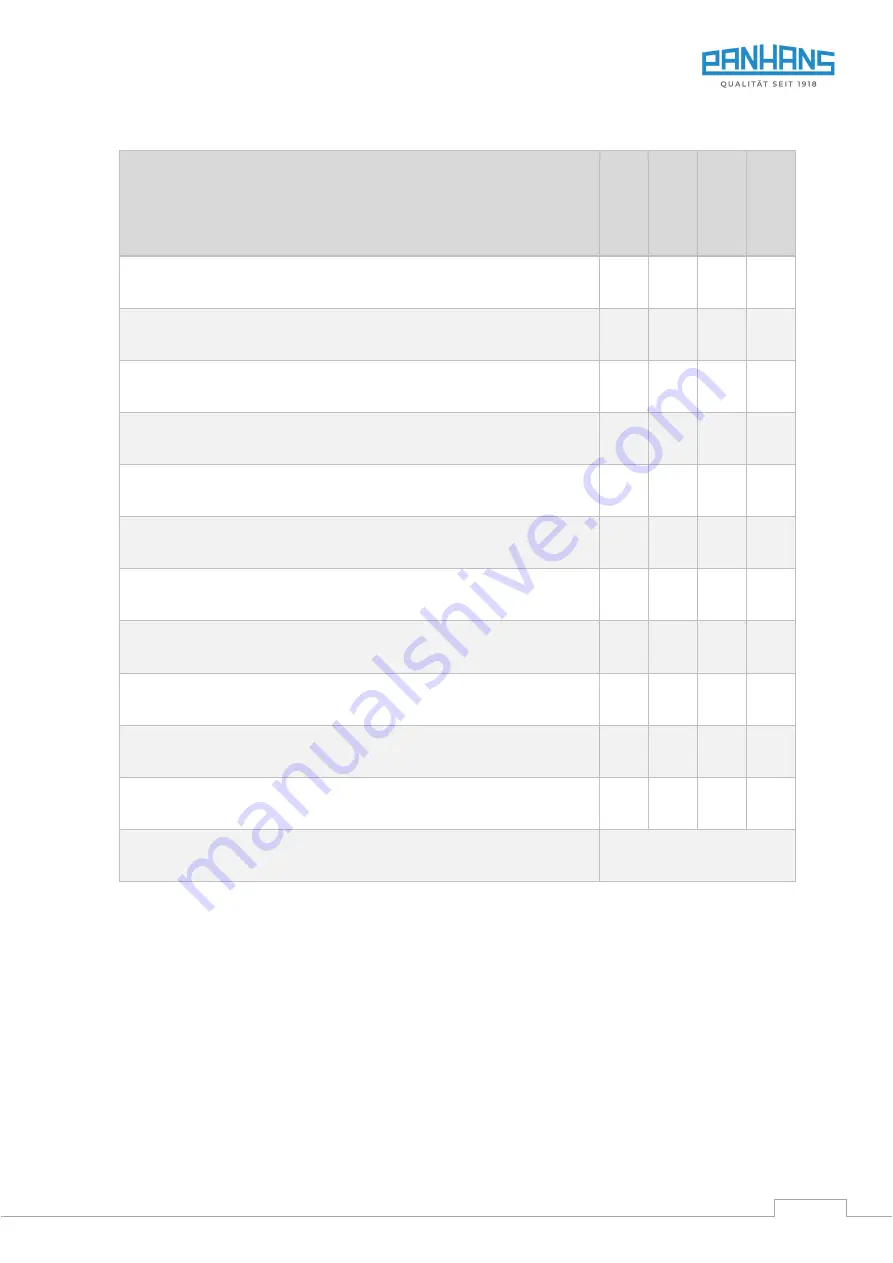

Maintenance Plan

Activity

da

ily

we

ek

ly

m

o

n

th

ly

an

n

u

all

y

Cleaning the machine

X

Check that the extraction system is fully functional before starting work.

X

Inspect electrical equipment and components for externally visible damage

and have this repaired by a qualified electrician if necessary.

X

Check drive belt condition.

X

Check drive belt tension.

X

Check all sliding and rolling parts for smooth running and lubricate with a

thin-bodied oil if necessary.

X

Apply a few drops of oil to the threads of the clamping & adjustment levers.

X

Clean swivel segments from resin and wood residues and lubricate with a

thin-bodied oil (e.g. Neoval).

X

Lubricate the milling spindle bearings at the marked points

(see section

X

Check the milling fence for damage and replace damaged parts if necessary.

X

Replace the lubricator of the swivel adjustment (for detailed procedure see

section

X

Check the TAPOA 1639 ring fence for damage

and replace damaged parts if necessary.

Always before use

In addition to the maintenance plan, please also follow the section

“Lubrication Plan”.