BA_PH_245-20_EN_15-22.docx

28

7.6

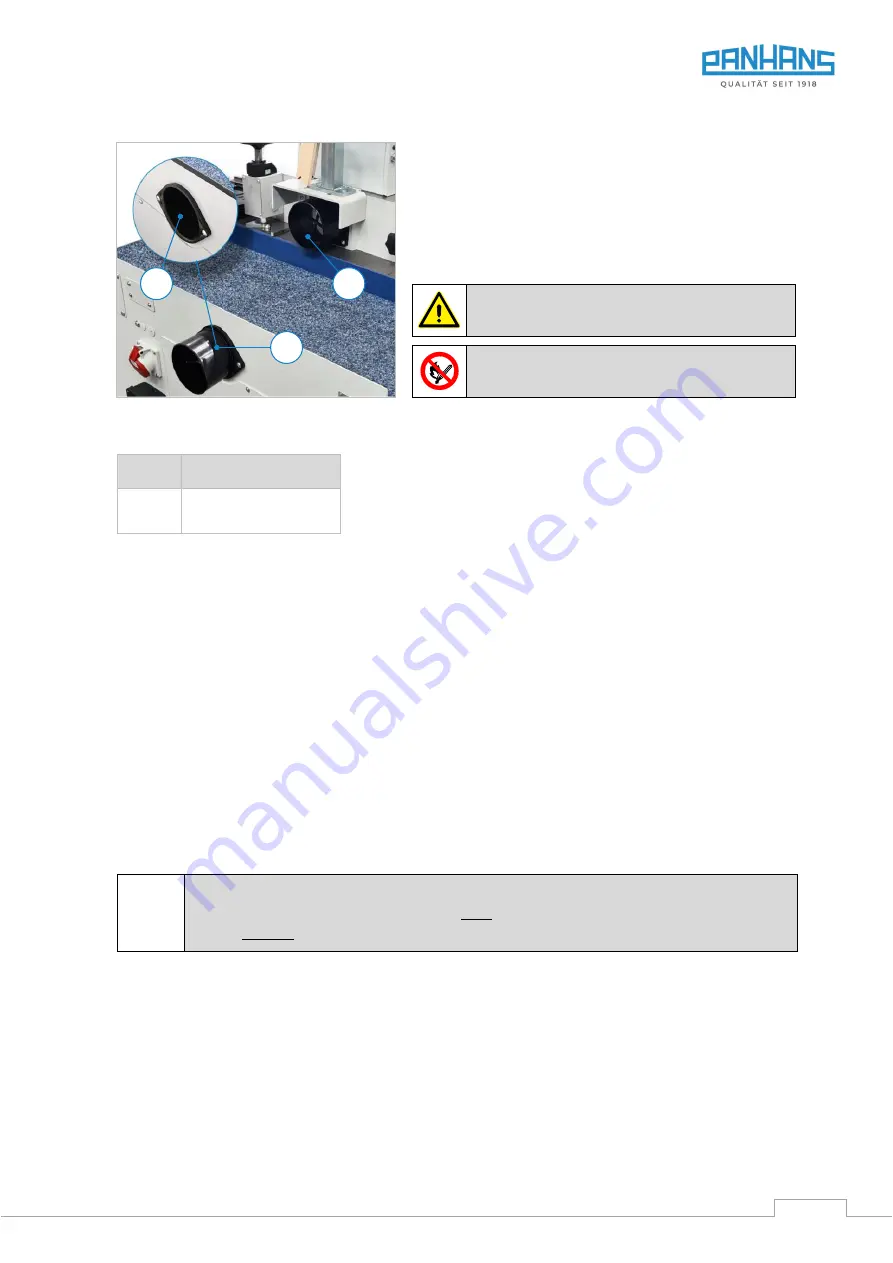

Connecting the Extraction Unit

Figure 8: Suction nozzles

The machine must be connected to an effective extraction sys-

tem on-site. The two extraction nozzles (

1

) and (

2

) each have

an outer diameter of 120 mm.

For transport reasons, the lower extraction socket in the stand

is mounted with the connection facing inwards (

1a

). Before

connecting the extraction unit, it must first be unscrewed,

turned to the outside and then mounted again (

1b

).

When the machine is switched on, the extraction

system must start automatically.

When flexible suction hoses are used, they must

be flame-retardant.

Two signal generator lines must be connected for automatic switching of the extraction system:

Version

Connection terminals

Please note:

The connection terminals for the extraction system shown

on the left apply to the standard machine. Depending on the equipment

or with older models, these may differ. The valid terminals for your ma-

chine can be found in the circuit diagram (see

control cabinet).

245|20

13

+

14

on contactor

K5

Installation only by a qualified electrician!

All parts of the extraction system, including hoses, must be included in the earthing measure.

7.6.1

Air Speed

The air speed must be set in such a way that, with the extraction line connected and the tools stationary, an

average air speed of

-

20 m/s (1450 m³/h) with dry chips,

-

28 m/s (2050 m³/h) with moist chips (moisture 18 % or more)

is achieved at the extraction nozzles.

7.6.2

Existing negative pressure at 20 m/s

-

on the milling fence: 640 Pa

-

under the table top: 300 Pa

•

The air velocity must be checked before initial commissioning and after significant changes.

•

The extraction system must be checked daily for obvious defects after initial commissioning

and monthly for effectiveness.

2

1b

1a