BA_PH_245-20_EN_15-22.docx

57

17

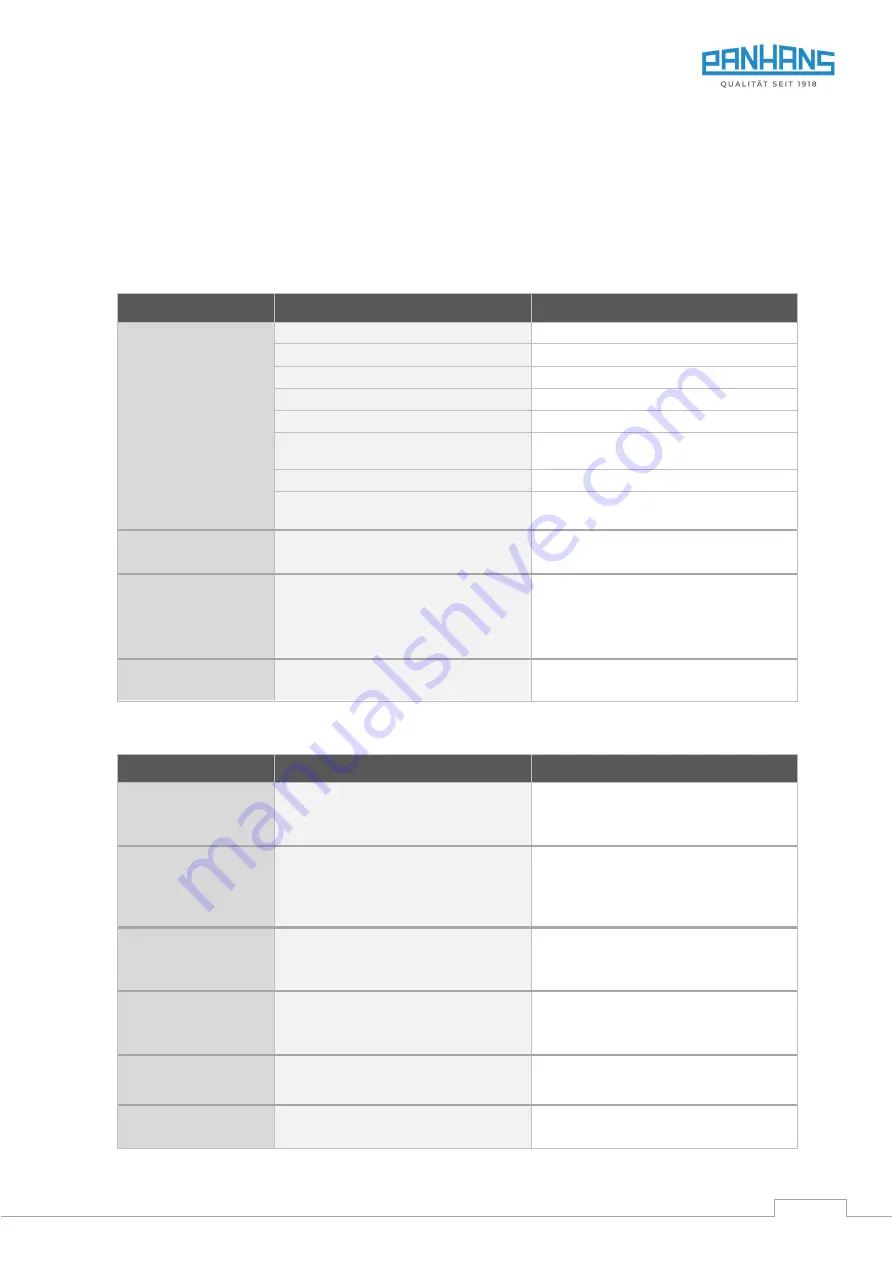

Troubleshooting

Proceed systematically when searching for the cause of a malfunction. If you are unable to find the fault or to

remedy the malfunction, contact our customer service department (phone number: 0049 7571 / 755 - 0).

Before you call us, please follow these steps:

•

Make a note of the type, machine number and year of production (see nameplate).

•

Keep this operating manual (and any circuit diagrams) to hand.

•

Describe the fault to us in detail so that a competent remedy can be found.

Fault

Possible Cause Remedy

Machine does

not start

No voltage

→

Check power supply (electrician!)

Control fuse defective

→

Replace fuse (electrician!)

Main switch defective

→

Replace main switch (electrician!)

Drive motor defective

→

Replace motor (customer service)

V-belt defective/loose

→

Replace/re-tighten V-belt (see

Motor protection

switch has tripped

→

Set switch to OFF

and then back to ON

Emergency stop button pressed

→

Pull/unlock button

Service door open

→

Close the service door

and lock the safety switch

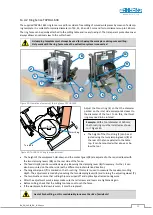

Spindle runs

unbraked out

Brake pads worn

or brake is defective

→

Readjust brake (see

→

Renew brake (customer service)

Speed display

does not work,

or control does

not indicate speed

Speed fork light barrier defective

V-belt does not run in fork

V-belt main saw torn

Fork light barrier dirty

→

Replace (electrician!)

→

see section (see

→

Replace V-belt (see

→

Clean fork light barrier

Spindle cannot

be not tilt

Limit switch for optional

table slide is active

→

Open the table slide completely

17.1

Error Messages of the Control Unit

Fault

Possible Cause Remedy

ESTOP

appears in the display

Emergency stop actuated

Emergency stop defective

→

Unlock button

→

Check button

→

Check wiring

ENCODE

appears in the display

Height adjustment motor defective

Swivel adjustment motor defective

Measuring system dirty / defective

Control unit defective

→

Check adjustment motors

→

Check wiring

→

Check sensors

→

Replace control unit

CURR

appears in the display

Overcurrent on swivel

or height adjustment

Sluggish mechanics

→

Clean machine

→

Lubricate spindles

→

Check adjustment motors

SHORT

appears in the display

Short circuit on

motor cable or motor

→

Restart machine

→

Check motor

→

Check control unit

E

appears in the display

Watchdog error

→

Press “Stop” button

→

Check control unit

E1

appears in the display

Watchdog error

→

Press “Stop” button

→

Check control unit