BA_PH_436-100_EN_44-21.docx

24

7.6

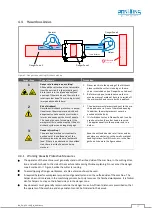

Connecting the Extraction Unit

•

The machine must be connected to an effective

extraction system on-site.

•

The suction nozzle has a diameter of 160 mm.

•

All parts of the extraction system, including hoses,

must be included in the earthing measure.

When flexible suction hoses are used,

they must be flame-retardant.

When the machine is switched on,

the extraction system must start

automatically.

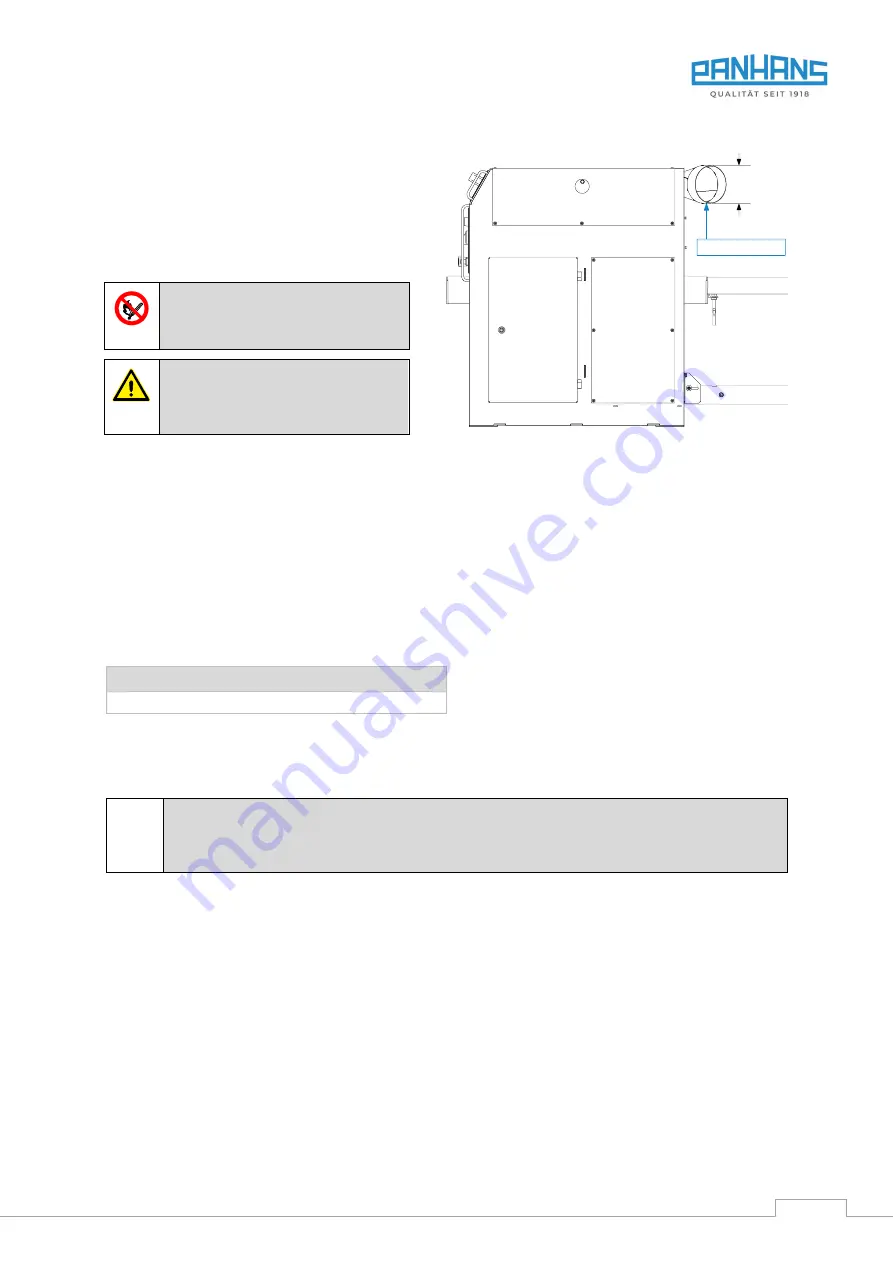

Figure 9: Extraction connection

Two signal generator lines for automatic switching of the extraction system can be connected to the terminals

13

and

14

of contactor

Q2

.

Installation only by a qualified electrician!

The air speed must be set in such a way that, with the extraction line connected and the tools stationary, an

average air speed of

-

20 m/s (1450 m³/h) for dry chips,

-

28 m/s (2050 m³/h) with moist chips (moisture 18 % or more)

is achieved at the extraction nozzles.

Required negative pressure (at 20 m/s)

600 Pa

If the machine is properly connected to the extraction system, it can be assumed that the wood dust assess-

ment value will be complied with (permanently and safely).

ø

1

6

0

Suction Nozzle

•

The air velocity must be checked before initial commissioning and after significant changes.

•

The extraction system must be checked daily for obvious defects after initial commissioning

and monthly for effectiveness

.